Watching

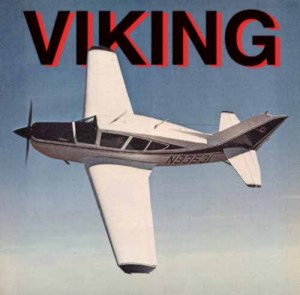

the angular arrow of wood and fabric taxi

onto the ramp, I couldn't help but marvel at

the history behind the Bellanca Viking,

whose basic design is actually far older

than I am. The plush EI Dorado interior and

space-age avionics may be a far cry from the

early pin-ball styling of the original 1937

Bellanca Junior, but the basic bones and

lines show that the Viking 300A and the

Junior are much more closely related than

many other aerial father-and-son acts now

being produced. The Viking graphically shows

just how far the industry has, or hasn't,

come in the past 37 years. It was far ahead

of its time when born, and is still

considered by many to be the Ferrari of the

four-place light airplane field, but in some

ways it's still an anachronism.

What an absolute headwrecker the original 14

series Bellanca Junior must have been when

it popped into the 1937 aviation scene.

Lean, trim, and so fast for its power as to

be sinful, it flitted around like a mosquito

among the Staggerwings and Reliants then in

vogue. Its happy little 90-hp Ken-Royce, or

LeBlond, radial could drag it along at over

120 mph and what a song that tiny round

engine must have sung.

The Viking can be had with 300 hp in the

nose from either Lycoming or Continental

After the war,

the cramped three-place fuselage of the

Junior and its radial engine gave way to an

equally cramped four-place cabin and a

motley procession of flat engines (120-,

150- and 165-horse Franklins; 190- and

230-hp Lycomings), but the lines and size

remained almost exactly the same. As I

looked over the 1974 Weld-wood wonder that I

was to explore for the weekend, I had to

remind myself that the vital statistics of

the Bellancas haven't changed a fraction of

an inch since the very first junior: 34 feet

of span and 161 square feet of wing to hold

it up. However, two other important numbers

have changed mightily over the years: The

cowling now stables 300 giant horses rather

than a very wobbly 90, and the Viking weighs

in 500 pounds heavier when empty (2,250

pounds) than the Junior did at gross (1,700

pounds). Unfortunately, modern performance

figures reflect the added weight more than

the higher horse-power.

The Viking has always been the darling of

the typewriter prophets, so it gets its

share of press coverage. Aviation writers

love to borrow a Viking and go romping off

to San Juan, Barbados or Peoria because the

airplane has so much class. Because of this,

you'd have to be a hermit not to know the

familiar "built by Old World craftsmen a

piece at a time" story. It's a theme that

would wear thin if it weren't so true.

Bellanca is the last builder of four-place

people haulers to hold out against

cookie-cutter assembly line methods. The

wood wings are the result of a 60-year love

affair with spruce, and really are built by

master elves a piece at a time. Modern glues

and sealers have made a good thing even

better. The factory is fond of pointing out

that there has never been a failure or an

airworthiness directive against a Bellanca

wing, regardless of age, and the stuff they

dip the finished wings in pushes any

possibility of rot far off. (Editorís

Note from 2003: They canít say that about

Bellanca wings any more. Only a couple years

after this was written, several lost wings

prompting a major flurry of ADís).

The jungle gym of chrome-moly tubing begins

at the motor mount and ends at the rudder

post, giving the passengers one of the best

crash-survivability structures flying. It's

not light, and it's not easy to build, but

it makes one hell of a crash cage. The

fuselage sets aircraft structures back 40

years, back to the days when you could hit

the ground pretty hard and not worry about

the airplane collapsing and wrapping itself

around you.

Both the wings and the fuselage get a

finishing cover of dacron and dopeóa

surprising change from the fibreglass cloth

they used during the '60s. Although the

Dacron's life will average only about 10

years (a number that varies drastically

depending on storage, use and care).

As any engineer will tell you, there's a lot

to be said for wooden wings; they have an

infinite fatigue life (almost), and they can

be made incredibly smooth. But they cost

more than the same animal in metal and not

only is quality spruce getting tough to

find, but finding men who are artists with

chisels is no easy task either.

The airplane I managed to con the factory

into giving me was a shiny, new 1974 job

with enough options and avionics to raise

the $34,400 base price up to a sizzling

$50,000 plus (From the 2003: that sounds

pretty silly now, doesnít it?).

I think I should mention from the very

beginning that I'm what's known as your

basic Bellanca buff. I've been flipped out

over them since the first time I wiggled

into a 230hp triple-tailed job years ago.

They've always been a hundred yards the

other side of ugly, and the Bellanca

engineers who designed the original

cardboard constellations must have thought

leg-room an unnecessary option. But they

were the best flying airplanes around.

Preflighting

the airplane revealed a curious combination

of intelligent innovation and questionable

planning. The cowl, for instance is a

well-made two-piece affair with two rather

smallish doors for access to the dip-stick

and oil filler cap. To inspect the engine

you either have to remove a bunch of screws

and split the cowl or be satisfied with

peeking through various holes. They were

thoughtful enough to mount a remote

gascolator drain right next to the dip stick

so you don't have to suffer through the

usual gas-down-the-elbow routine while

fumbling under the nose for the quick drain.

I like that little bit of added convenience.

The wing drains, on the other hand, are

almost totally invisible, being mounted

inside the bottom of the wing and reached

through a small, nail-sized hole. To drain

them you must use a special cup supplied by

Bellanca that has a plunger sticking up out

of it, which you insert in the wing hole and

push. It's an extremely clever and

aerodynamically clean way to handle the tank

drains, but it takes a lot of scrounging

around and knee-dirtying to get at them.

Even the Bellanca sales type who was

checking me out had trouble locating the

drains. There has to be a better way.

Throughout its long career, Bellanca has

always had a reputation for building

spectacular performing airplanes with rather

unspectacular, dowdy interiors and panels,

but the Viking has changed that image once

and for all. As I popped the door open and

slid across into the left seat, I was

knocked out by the plushness that leaped up

and sucked me inside. Boarding may not lend

itself to displaying your more graceful

movements, but the contortions have their

rewards because the entire cabin reeks of

class and incredible detail. Only the tiny

remnants of a piece of masking tape on a

window frame kept the cabin from being a

hundred-point concours winner, but

ninety-nine sure ain't bad. Absolutely

nothing else being produced touches it.

This particular demonstrator was done in a

zowie blue naugahyde and fabric that was

brilliant, but at the same time very

tasteful. The only gripe heard from those

who romped through this aerial playroom with

me was about the headliner material. It's a

blue version of the usually mouse-coloured

mohair that '48 Hudsons and others used so

ineffectively. It looked like it would dirty

very quickly and the texture didn't come up

the modern levels set by the rest of the

interior. A vinyl headliner is available as

an option and would sure be worth the extra

bucks.

The panel is exactly what an airplane

instrument panel should be. There are no

cutesy design gimmicks aimed at hiding the

fact that you're in an airplane, like the

all-too-familiar plastic and fake wood

automotive syndrome. Rather, it's black and

businesslike with most of the goodies right

where they should be. A number of the engine

instruments (manifold pressure and

tachometer included) are the vertical kind

with floating needle indicators. They were

almost impossible to read at first, but

inside of an hour or so they became as

familiar as the old-fashioned clock gauges.

It's easy to

see why Bellanca is using so many vertical

gauges-they need the room. The limited

cockpit depth means the panel must jut

upward a fair amount to give enough space to

mount the array of gadgets most modern

pilots think they need. But, even with a

sizeable hump in the panel, they've had to

squeeze switches and knobs into just about

every corner of the panel and onto consoles

on both sides of the cockpit.

The only thing about the entire airplane

that struck me as being just plain stupid

was the location of the fire extinguisher.

It's on the floor behind the pilot's seat,

precisely where he can't reach it and the

passenger can't avoid it. That doesn't show

much planning. However, balancing off the

fire extinguisher faux pas is the placement

of the fuel selector and tank gauges. The

selector is between the seats and is one of

the easiest to work and best located ones

I've ever seen. The selector is coupled with

a system of lights under the fuel gauges.

The selector lights the bulb below the

indicator of the tank that's in use, so

there's no guessing about whether or not

you're working on the fullest tank.

As I strapped in, I mentally gave Bellanca a

gold star for mounting shoulder harnesses

(cross-over chest belts that snap into the

top of the seatbelt buckles) that are both

effective and comfortable. Since I planned

to sneak into the far corners of the

Viking's flight envelope, the belts made me

feel a little more secure. More

manufacturers should show the same concern.

The Viking that the factory decided to risk

in my hot little hands was powered by a

300-hp Continental rather than the Lycoming

option of the same horsepower. The Lycoming

costs an additional $1,870. The Continental

rating of 300 horses is good only at takeoff

settings and max-continuous is 285 hp. The

starting procedures for the Continental are

a little weird because you just shove

everything to the firewall-throttle, mixture

and all-and start cranking. A shot of primer

from the three-position boost pump switch

gets fuel pressure up to keep the fire lit.

This boost pump switch, incidentally, is one

of the several important controls that are

hidden by the yoke. Following the

recommended starting procedures rewarded us

with lots of noise immediately, but later we

played with different types of starting

techniques and found you could usually treat

it like any other big fuel-injected engine.

The Viking is cursed with one of those

gadgets that many swear by, and others swear

at: the vernier throttle. Words cannot

describe my own loathing of the vernier.

It's a pain to taxi with and proved to be an

even bigger problem during touch-and-goes in

turbulence. Every pilot who flew the

airplane with me had the same remark, "Get

rid of that lousy vernier." There are a lot

of situations in which it's nice to have,

but when you need lots of power in a hurry,

the vernier can prove disastrous. To be

fair, though, it must be mentioned that both

Cessna's and Beech's big singles have

verniers.

The first

takeoff was memorable only because nothing

happened. The airplane was in the worst

possible situation: warmish temperatures,

gusty wind with hard-edged turbulence, and

we were full up with all seats occupied and

all the gas we could cram into the two

30-gallon wing tanks. As the throttle went

in, the noise built to a pretty respectable

din (even though we had the three-blade

option, which is supposed to be quieter) and

we were pushed further and further back into

our seats as the IAS lunged toward takeoff

speed. With a little coaxing from my check

pilot, Bill Briggs, I lightened the nose at

60 IAS and lifted off at 80 mph. The second

we were off the ground the airplane let it

be known that it wanted to climb. There was

no hesitation, no riding on ground effect.

Just a healthy leap off the runway into a

stable climb.

As I jerked the gear up, Briggs leaned over

and shouted (he had to to be heard) in my

ear "Don't bring the power back below 90 mph

or the gear will come out again."

"Oh, fantastic!" I thought. I had one of

those idiot proof gears aboard. Hiding it

under the not-too-clever name of Auto-Axtion,

Bellanca has seen fit to protect us from

ourselves and our insurance companies by

fit-ting the Vikings with an automatic gear

extension system. Theirs makes more sense

than some, but it has its drawbacks. The

gear automatically goes down anytime the IAS

drops be-low 90 mph unless the throttle is

full open or the master is off. So, if you

don't keep your hand to the wall under 90

mph, you'll be greeted by three winking

lights on the panel. Once you've hit 105

mph, it's supposed to retract again.

Cleaned up and accelerated to a climb speed

of 110 mph, we showed a welcomed 1,000 fpm

plus on the VSI, which got us out of some

fairly severe ground turbulence pronto. When

light, the Viking is a real climbing fool.

The second I cranked over into a left turn

to head for Boston, I fell in love with

Bellancas all over again. Their ailerons are

sensuously smooth and the roll rate is quick

and tight. At first there's a slight

tendency to over-control in roll when

fighting turbulence, but that disappears

quickly, leaving you with the feeling that

you're flying a four-place Pitts.

However, as much as I loved the ailerons, I

hated the elevators, and this proved to be

one of the more irritating aspects of the

Viking to almost everybody I introduced it

to. They didn't like the control harmony, or

the lack of it. The combination of light

quick ailerons, relatively heavy elevators

and a moderately ineffective rudder goes a

long way toward ruining the grace of the

airplane. It's like dancing with a

beautifully agile girl who's wearing combat

boots. Although, with that short tail,

lightening the elevators too much might

cause new pilots to porpoise.

In cruise, those firm elevators combined

with the short tail moment make just about

everybody, myself included, work to hold an

accurate altitude. It just didn't want to

sit in one place, especially in rough air.

If you displace the nose suddenly by jabbing

the yoke, it takes nearly four oscillations,

at a minute apiece, to dampen the movement.

Then it sits at a particular speed and

altitude until the next bump and starts

searching all over again. If I were to do a

lot of IFR work in it, I think I'd like to

have the altitude-hold, which is offered as

a Century series autopilot option.

I've got to give Bellanca a lot of credit

for being one of the few totally honest

companies when it comes to performance

figures. We actually found some of their

numbers a bit conservative. At 75 percent of

power, we consistently indicated 180 to 185

mph and were trueing 190 mph and up, while

Bellanca lists only 187 mph in their

advertising.

You really feel like an airline pilot when

you're humming along in a Viking at 11,500

feet on top of a broken deck, squawking

1400, playfully switching the DME mode back

and forth and watching minutes and knots

magically appear in the windows. This is the

domain of the Viking. Running high and fast,

getting the driver from here to there as

quickly as possible.

Since altitude steals manifold pressure

quickly, the turbocharger option, worth an

additional (and incredible) $8,000 and 20 to

40 mph (223 mph at 24,000 feet!) could

really put a head on the high-altitude

experience.

As we neared Boston; where I was to drop

Bill Briggs, Bellanca regional manager, we

lowered the nose and shot down through a

gigantic (and legal) rift in the clouds

showing 2,500 to 3,000 fpm down on the VSI.

The handbook says emergency letdowns can

give as much as 4,500 fpm, if needed. Now,

that's what I call coming down!

As soon as the airport was in sight, Briggs

started talking about pilots who have

trouble landing the airplane because they

play with the throttle too much and don't

adhere to the recommended method of setting

it up on final at 90 mph and 15 inches and

flying it right onto the runway. He was

trying to offer me advice in a subtle

manner. I pretty much ignored him, as I

still felt very awkward in the machine and

was working much harder than I had expected

to.

With the gear out at 140 mph, I started

messing with the power, and, as predicted,

found myself bobbing all over the glide

path. The sink rate, even at pattern

altitude, seemed to build up very fast when

the power was reduced, but at the time I

didn't think much about it. After I left the

throttle alone, the Viking flew the pattern

as if it knew where it was going, and I kept

the power on right into the flare, screwing

the throttle out as I brought the nose up.

It was a near grease job, or as close as I

ever get, and I had no problem keeping the

nose up as long as I wanted.

The nose gear is direct steering, like a

Cherokee, so it stays cocked if you have a

little rudder in it. I held the nose up long

enough to make sure things were square with

the world so the nosewheel wouldn't jerk us

to one side.

With the amenities of borrowing the airplane

completed (I promised Briggs I'd bring his

airplane back), we loaded up for the trip

home. As I was rolling back onto the runway,

I congratulated myself for being such an

ace, transitioning to this hot, new

superbird so smoothly. But my delusions of

aeronautical grandeur were short-lived, as

my next landing poked a lot of holes in my

ego and taught me a lot more about the

Viking.

I work out of a tiny airport in north Jersey

that's got some of the strangest winds

around. Its 2,000 feet of asphalt actually

jut out into lakes at either end, forming

aircraft-carrier type fan-tails four or five

feet higher than the adjacent water. Combine

this with high ridges on either side of the

runway and you have the makings for all

sorts of violent turbulence right off the

end of the runway. It may not sound like

much, but on windy days, it's been known to

humble more than a few hotshots.

As I got the flaps out and turned final, I

thought I had the airplane and the airport

psyched out. With the sink rate of the

Viking, I figured all I'd have to do was

cautiously jockey the power to stay on glide

path and put the mains right on the end of

the runway.

I had expected some downers and was ready to

fight them, but even though I knew what to

expect, things went to hell in a hurry. I

suddenly found myself very busy fighting

turbulence while keeping that damned vernier

release knob depressed. The airplane just

wasn't reacting the way I expected. When a

downdraft would start sucking us toward the

water, I'd hit the power, but it didn't take

effect until we were into the next updraft

and then I had to yank it off. When I saw I

had the runway made, I committed the final

mistake-I pulled the power off. The

airplane's natural sink rate combined with a

slight downdraft, and threw us toward the

runway at a frightening rate. It happened so

quickly that all I could do was yank the

nose up before contact. Thanks to a fat

cushion of ground effect, the touchdown

wasn't hard at all, but we were skating

along like a shuffleboard puck on a freshly

waxed board. To make matters worse, on

rollout I let the cocked nose wheel touch

the runway for a second, which yanked us off

the centreline rather abruptly. Chalk one up

for the airplane.

After thinking about it for a while, I

thought I'd figured out my problems with the

airplane, but I wanted to see if other

pilots had the same hang-ups. Besides, some

of Bellanca's advertising prose says "docile

as a trainer," and "gentle as a lamb," and I

wanted to check that out on a bunch of

different pilots with varying skill levels.

So, the next morning I rounded up a herd of

local tire kickers including a fairly

low-time Mooney owner, a flight instructor,

a Debonair owner and a couple of airline

pilots.

I sat in the right seat and watched all

these pilots go through the same

embarrassing short-field learning process I

did. The problem seemed to center around

controlling the sink rate in turbulence, and

the vernier throttle. Only the airline types

got by without having the airplane fall out

from under them on at least one landing.

In researching the problem, I went upstairs

and played a little with sink rates. At the

prescribed 15 inches, with gear and full

flaps, the Viking comes down at a very

comfortable 700 to 800 fpm, about like a

power-off Cherokee. Screw the power out just

a smidgen, to 12 to 13 inches and the VSI

leaps up to something in the neighbourhood

of 1,200 fpm. Bring it all the way out and

the needle rockets up to 1,800 to 2,000 fpm,

and that's a fantastic sink rate for a

single-engine airplane. All of this was

happening at an indicated airspeed of 90

mph. At slower speeds it's even more

dependent on power.

One of the really surprising aspects of the

Viking's slow-speed characteristics is the

gentle nature of its stall. Power off, it

runs out of elevator and either breaks

slightly or just continues mushing at around

70 mph. But with 15 inches of manifold

pressure, we were down around 55 mph at full

gross before anything started to happen and

then we had the wheel all the way back and

were only sinking about 500 fpm.

Knowing how the power affected the sink

rate, I started cautioning the troops about

not making large power reductions on final,

which helped a lot, but didn't completely

solve the problem. We still couldn't get the

hang of maintaining an exact glide path

through turbulence to land on a prescribed

spot. If we ignored landing on a spot and

held the power to go motoring right down on

to the first quarter of the runway, the

airplane was a pussycat to land, even in the

gusty wind. But, trying to punch holes in

turbulence to put it right on the end of the

concrete still caused all sorts of problems.

Still puzzled, I did a little more

high-altitude research with the sink rates,

this time not how to start them, but how to

stop them on command. It turned out that

while it takes a reduction of only a couple

of inches of manifold pressure to start the

sink rate, it takes a pretty healthy poke

with the go-stick to stop it. In the case of

a 1,500fpm sink, it took nearly 20 inches to

stop it immediately. This is exactly how

most super-high performance birds fly, even

jets. Once you get a sink rate or

deceleration rate started, it takes the

"lucky three"-time, power, altitude-to get

it stopped.

Something that would make the entire Viking

landing process a lot less troublesome would

be a different type of flap switch setup. As

now designed, you can only select two flap

positions, 23 degrees and a whopping 45

degrees, nothing in between. The pilot has

to be able to pick other flap settings,

preferably with a continuous action switch,

so the switch could be pushed down to a

certain point and the flaps would stop at

the deflection indicated. That way, you

could set up a power setting and partially

control the glide path by dropping flaps a

little at a time. Right now, when you go for

the last notch, you've got a pretty healthy

pitch and speed change to watch for. That's

one reason the recommended procedure is to

get all the flaps out at least halfway down

final.

Also, I wish they'd relocate the flap switch

because I got tired of guys fondling my left

knee as they reached under the passenger's

wheel for the flaps. And the gear lights

should be moved up to the top of the panel

so they'd be easier to cross-check just

before touchdown. Now they are at the

extreme bottom of the panel, partially

hidden by the yoke.

I should probably make the point that in

nine out of 10 situations the Viking is only

marginally more demanding than most

airplanes of the species. Okay, so it's no

Piper Cub and it asks that you fly it

strictly by the numbers, but it's this

subliminal challenge to improve your

piloting technique that makes the airplane

so attractive to so many. Ferraris,

Aston-Martins and the like are far from

being easy cars to drive well. The Viking

falls into the same macho-machine category.

Once you've learned to handle its few

idiosyncrasies, the performance and the gut

feeling of personal accomplishment you're

rewarded with is well worth the effort.

Incidentally, when the turbulence died down

a little, we found we had no problem at all

in getting down and stopped in 1,000 feet.

Bellanca has a brand-new management and

engineering team that has taken dead aim at

the Viking's problems. Because of that, I

predict the next two years will see the

Viking cruising well over 200 mph with the

same engine, and its overall efficiency and

handling characteristics will be fine-tuned

to make the airplane easier for more people

to live with. This is important if they hope

to persuade Skylane and Arrow drivers to

transition into their airplane. As it is

now, a low-time Skylane pilot would age 10

years during his first Viking approach into

a short field on a rough day.

At a sticker price of $34,000, the Viking

really has very little direct competition.

It's most often compared to the Bonanza,

which isn't really fair since the Bonanza

costs a frightening $47,000. The Rockwell

Commander 112 starts at a tad under $30,000

as does the new production Mooney 21. For

$39,000 you get a lot more room and load

capacity in a Cessna Centurion, but it would

take a Centurion II at $44,000 to come even

close to the Viking's interior appointments.

One other problem in buying a Viking is

finding your local Viking dealer so you can

get a ride. The location of Viking dealers

is the best-kept secret in aviation. If you

want to try a Viking on for size, call the

factory in Alexandria, Minnesota, and have

them point you in the right direction.

I wish Bellanca had the money to match their

enthusiasm. I think they've got the right

combination of people and mental attitude to

build an all-new airplane based on the

Viking's concept of performance, handling

and interior, but using modern materials and

techniques. It would be a world beater.

Unfortunately, FAA certification being what

it is, both expensive and lengthy, we'll

probably see the same Bellanca airframe STCd

beyond recognition and produced for another

37 years. Oh well, worse things have

happened. But somehow, I just can't see a

spruce-and-tube airplane with a fanjet-or

can I?