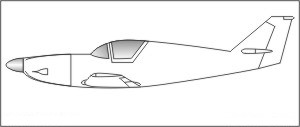

The Glasair was the first kit aircraft that used

moulded surfaces rather than the Rutan method of construction. The

original Glasair 1 required a very long time to construct, but the

newer kits are comparable with other complex kit aircraft. Fast

build options are available. The original company, Stoddard

Hamilton, (named after the late designer) went into liquidation due

to reasons outside the Glasair range. Fortunately the company was

purchased by aircraft enthusiast Thomas W. Wathen and is now going from

strength to strength.

The Glasair is the ideal long distance fast personal

aircraft. These aircraft are not only extremely strong, but fly

better than almost any experimental. They are renowned for their

handling characteristics. In addition, the resins used very rarely

cause allergy problems for builders. The Glasair III is renowned for its performance.

In its evolution from the earliest Glasair models, the III has

grown 30" in overall fuselage length, both forward and aft of

the cockpit. The increased length has given the III markedly

improved longitudinal and directional stability, making it an

impressive platform for serious cross-country and IFR flying.

(The Super II line incorporates these changes as well.)

Since the

Glasair III cruises at speeds up to 313 mph, the factory-moulded

fuselage halves of the III feature incorporate two additional

layers of fibreglass in the outer skin laminates behind the

cockpit to significantly increase the torsional rigidity of

the aft fuselage. Two composite ribs located inside the

vertical fin are bonded to the horizontal stabilizer to

increase stiffness in this area as well.

The belly

section of the III fuselage is stronger and stiffer than that

of the Super II, and it incorporates a strong multiple-screw

and nutplate attachment in the centre section for ease of

removal. The forward belly panel comes with pre-moulded cooling

air exit ramps designed to optimize engine cooling and exhaust

installation for the III’s six-cylinder engine.

The well for

the retractable nose wheel is supplied as a pre-moulded

composite part with high-density foam core inserts moulded in

for attachment of both the nose wheel doors and the rudder

pedals on the inside of the cockpit.

Fire-retardant, closed cell polyurethane foam core is used in

all areas of the III fuselage, including the firewall.

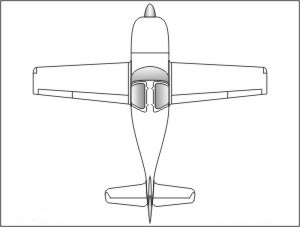

Wing

The Glasair

III’s wing span and area are the same as those of the Super II

-- 23', 3" and 81.3 sq. ft., respectively. However, the lower

aft surface of the LS(1)-0413 airfoil has been modified in the

aileron and flap area on the III to reduce induced drag,

profile drag and trim drag. This change, coupled with the

upswept Hoerner tips, provides light aileron forces even at

higher speeds.

To provide

the additional strength required for the 335 mph redline speed

of the III, extra laminates are moulded into the wing skins and

spars. In addition, the main spar attach fittings and the wing

attach support brackets on the fuselage are larger than their

counterparts on the Super II, and the composite airframe

structure around the wing attach points has received extra

reinforcement.

The Glasair

III wing features pre-moulded main landing gear support boxes.

These rigid, structural boxes eliminate the majority of the

laminating and jigging work on the main landing gear

installation and simplify the job considerably.

Control

Surfaces

The Glasair

III uses the same horizontal stabilizer airfoil section as the

Super II. However, graphite fibers have been incorporated into

the skin laminates of the III stabilizer and the span has been

shortened compared to the Super II to obtain the higher degree

of stiffness and torsional rigidity prescribed by our in-depth

vibration testing and computer flutter analysis.

The III also

features larger-diameter aluminium push-pull tubes for the

aileron and elevator control systems than earlier Glasair

models, providing increased column load capacity. Increased

mechanical advantage is provided in the flap control system,

which has been designed to reduce the effort required for flap

actuation while maintaining a simple manual linkage.

Electrically actuated flaps, both standard and slotted, are

available as options.

Landing

Gear

Durable

oleo-pneumatic landing gear struts are used for all three

wheels on the Glasair III. These are top quality, rugged and

designed with low-maintenance features throughout. Internal

fluid metering has been customized for the Glasair’s weight to

give smooth taxiing over rough ground, as well as proper

damping for hard landings. The internal parts are designed so

that specialized wrenches are not required for disassembly,

and service can, if necessary, be accomplished by a novice

with the detailed service instructions New Glasair LLC - New

GlaStar LLC provides.

The landing

gear is retracted by an electro-hydraulic pump driving

actuating cylinders. The complete retraction cycle takes about

ten seconds. The gear is controlled by a switch on the

instrument panel and monitored with a panel-mounted hydraulic

pressure gauge and three gear position lights. The lights

indicate gear down and locked (green), gear in transit (red),

and gear up and locked (lights out). Additionally, a warning

horn is activated if the flaps are lowered prior to gear

extension.

The III also

features a gear up-lock system, which is essential for any

high-performance retractable-gear airplane, especially one

that may be subjected to high-G, aerobatic manoeuvring. The

up-locks release automatically when the hydraulic actuators

begin their cycle.

Another

standard system on the III is a cockpit-operated, manual

system for emergency gear extension -- obviously an important

safety feature. The system, which utilizes a hand pump and

special single-direction actuators, is completely separate

from the main hydraulic system, providing true redundancy in

the event of a malfunction.

The massive

oleo nose gear installation mates to the engine mount in a

simple, bolt-on operation. The strut features a heavy-duty

machined shimmy damper collar, which is important for high

speed taxiing. The nose wheel of the III -- like all

tricycle-geared Glasairs -- is free-castoring. Steering on the

ground is accomplished with differential braking at very slow

speeds and using the remarkably effective rudder at higher

taxi and take-off speeds.

The landing

gear also features a powerful braking system including master

cylinders, reservoir, aluminium tubing brake lines, fittings

and heavy-duty brakes. These brakes use 3/8"-thick discs,

which provide better heat dissipation and permit higher piston

forces on the pads than standard, 5.00 x 5 brakes.

Cowling

The Glasair

III cowling has been optimized to provide outstanding engine

cooling with minimal aerodynamic drag. The protruding exhaust

tunnel common on other Glasair models has been eliminated on

the III in favor of twin exhaust stacks that protrude only

slightly beyond the cowling. This change greatly reduces drag

by allowing for a sleek, uninterrupted belly contour from

spinner tip to tail.

The III

cowling is manufactured with extra stiffness because of the

airplane’s high-speed capability. The cowling halves are made

exclusively with special fire-retardant resin and foam core

materials.

The oil

access door is factory-moulded and ready to install into a

moulded inset in the upper cowling. A flush-fit landing light

lens sized to fit a moulded recess in the lower cowling is also

a standard kit feature.

Engine

The Glasair

III uses a certified Lycoming aircraft engine. With such

exciting cross-country capabilities, having a proven, reliable

engine is a must.

The

Glasair III is designed to use the most readily available 300

hp Lycoming engine, the IO-540-K series. The engine installed

in our prototype III is a smooth-operating -K1H5. This engine

has the fuel injector mounted on a straight air inlet housing

on the aft side of the engine oil sump. It is equipped with a

Bendix RSA-10ED1 fuel injector, a diaphragm-type fuel pump and

drive, and two impulse coupling magnetos.

The

IO-540-K1H5 engine can be purchased new direct from New

Glasair LLC - New GlaStar LLC at an attractive, original

equipment manufacturer’s (OEM) price, but this engine is

unlikely to be found on the used or overhauled market, since

it is not used on any production aircraft. Several 300 hp

IO-540 models that do show up frequently for sale can be used

in the III, however.

The factor

that determines which models can easily be used is the engine

induction system. Induction air in the III is routed from a

NACA duct on the left side of the cowling through a full-time

air filter connected to the injector body by a moulded flex

coupling. The injector is mounted sideways in the cowling on a

90° steel elbow (supplied in the standard kit) that fits onto

the engine’s air inlet housing. In order to obtain the proper

firewall and engine mount clearance for this induction system,

a straight (rather than angled) air inlet housing must be used

on the rear of the oil sump.

Because they

were used in the Piper Cherokee Six, the 300 hp IO-540-K1A5

and -K1A5D (with impulse coupling magnetos) are widely

available as used engines and would be good choices for the

Glasair III. These engines used aft-mounted, 38-1/2° offset

air inlet housings instead of the required straight housing,

but exchanging housings is a simple and relatively inexpensive

operation.

Note: The

common fuel pump on the Cherokees was the smaller but very

expensive Lear-Romec style.

The 300 hp

IO-540-K1E5, used on the Bellanca Viking, is also readily

available used. It comes with the straight air inlet housing,

Lear-Romec fuel pump, and Bendix RS-type fuel injector. This

style of Bendix injector, unfortunately, is not optimal for

use in the Glasair III. If you want to use this engine, we

recommend exchanging the RS injector for an RSA-10ED1

injector.

Note:

Many other models of the Lycoming IO-540 can be modified for

use in the Glasair III. If you find a great deal on an engine

not discussed above, call our Builder Support Department for

advice.

Propeller

Both

80"-diameter Hartzell and 79"-diameter McCauley Blackmack

two-bladed, compact-hub constant-speed propellers can be used

on the Glasair III. After extensive testing, two-bladed props

were selected over three-bladed models due to their

efficiency, lighter weight and lower cost. The landing gear

legs are sized to give a healthy 10" of ground clearance with

either of these props.

The prop is

not included in the kit, but a complete spinner installation

is standard. The composite spinner is manufactured to

perfectly match the loft lines of the Glasair cowling.

Hartzell and McCauley propellers are available, factory-new,

at OEM prices direct from New Glasair LLC - New GlaStar LLC.

specifications

powerplant

propeller

length

height

wing span

wing area

seats

empty weight

useful load

gross weight

fuel capacity

range |

300 h.p.

x

21.3 ft

7.5 ft

23.3 ft

81.3 sq ft

2

x

x

2,400 lbs

65 gal

8 gal header Tank

11 gal

Wing Tip Extensions

1100 |

performance

takeoff distance,

ground roll

rate of climb

max speed

cruise speed

landing distance, ground roll

service ceiling |

x

2990 ft/min

260 knots

272 knots (turbo)

x

30,000+ ft.

Turbocharged |

limiting and recommended speeds

design manoeuvring speed (Va)

never exceed speed (Vne)

stall, power off (Vsl)

landing approach speed |

174 knots

291 knots

69 knots

x |

All specifications are based on manufacturer's

calculations |