|

The early 30's

aviation design bureau, lead by K.A.Kalinin, was a capable aircraft

design team. One of their projects was a 3-engined passenger aircraft,

the K-7, also designated as "K-Tjazholij" (K-Heavy) for the new 500hp

German BMW "Hornet" engine. It was designed to carry 22 passengers. The

mock-up prototype was tested in the TsAGI wind tunnel in September

1928, and was approved for production by the Scientific-Technical

Commetee VVS in March following year.

However, production was not started, and the designation K-7 was used

again for a transcontinental aircraft project, begun in 1928. 'The idea

to built K-7, (K.A.Kalinin wrote later), came to me long ago, as early

as 1925. In 1929 the project was formulated and after two years of

refinement it started to come to life... With the larger engines

available it was possible to consider building aircraft capable of much

greater carrying capacity. This led to the design of a flying wing. The

new philosophy was "everything is in the wing"'.

The original aircraft design was all-wood with a 5-spar wing. But it

became clear that it would suffer from lack of strength, and after much

discussion, K.A.Kalinin decided to switch to an all-metal welded

construction with a 3-spar wing.

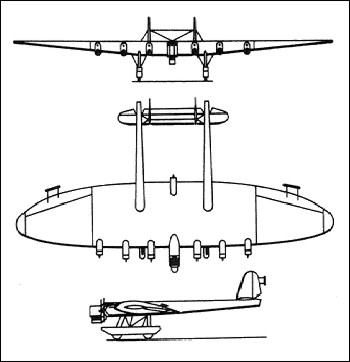

The K-7 was a gigantic elliptical wing of extremely thick airfoil (span

53m, area 452m2) with two triangle section tail booms, carrying tail

fin and tail plane with control mechanisms. The straight wing (width

6m, length 10m, height 2.33m) had room for payload and people.

Elliptical consoles with 14 fuel tanks were attached to the centroplane.

The centre was covered with duralumin, consoles with fabric. There were

no thick tubes able to comply with the requirements of the central spar

so it was made of two parallel tubes. The rest of the wing frame also

was made of welded steel tubes.

A nacelle protruded from the leading edge, with a cockpit for two

pilots, navigator, radio-navigator and chief mechanic. Seven more crew

members were located in other sections of aircraft and communicating by

internal telephone.

The aircraft was

designed for 6 BMW engines, but a later decision was made to install

Russian made AM-34s. The six water-cooled engines lacked power, and

K.A.Kalinin was forced to add a 7th pusher engine on the trailing edge

of the wing between the tail booms. The designer was aware that this

engine would increase airflow turbulence and would lead to vibration of

the aircraft, but he had no other choice. Early AM-34 engines were not

equipped with gearboxes and had power of only 750hp.

The triangular tail booms protruded from the last spar to the tail. The

tail booms were equipped with tailwheels, protecting the tail from

contact with the ground. The original main gear design allowed the

aircraft to be horizontal while on the ground. The main gear consisted

of two widely placed gears of frame design with oil-pneumatic wheel

suspension, the first attempt in Soviet heavy aircraft.

Each main gear had 3 wheels and were covered with fairings - the left

gear had an entry door and stairs leading into the wing.

At the design stage it

became clear that it would be hard for the pilot to control the plane

because of the enormous load on the controls. For the original design,

K.A.Kalinin proposed electric 'boosters'. A contract was signed with

one of Moscow electro-technic institutions, which undertook to develop

and manufacture the new system. But they failed to do so, and the

control planes of the K-7 were equipped with control surfaces, placed

on light booms.

Theoretical problems of heavy aircraft control by use of control

surfaces were solved by the aerodynamic team lead by N.F.Freiman. On

the TsAGI wind tunnel more than 300 successful tests were performed,

and in 1932 the surfaces were tested on the K-5 flying laboratory. The

system workedperfectly, and it was recommended to install them on the

K-7.

K.A.Kalinin also decided to use chromium-molybdenum tubes for the

aircraft frame - it was the very first use of such tubes in Russia.

Calculations for the frame were lead by Professor A.S.Balinsky - a

prominent scientist in the field of materials strength. Sadly, aircraft

was already overweight while still in the design phase, because

calculations had to take into account loss of strength of tubes near

wielded joints.

Steel tube production started (at the same time as the aircraft design)

at the Dnepropetrovsk Metal Works. Until now, tubes were imported from

Sweden, and to buy tubes for a single K-7 could cost as much as 100,000

golden Roubles. The TsAGI commission noted in 1932, the K-7 represented

a big step forward in aircraft design being the first to employ the use

of chrome-molybdenum tubes in the USSR.

The K-7 was designed as a multipurpose civil and military aircraft. One

of passenger options was developed to carry 128 passengers up to

5,000km. Another design - "luxe" - was supposed to arrange 16 luxury

cabins for 64 passengers. The aircraft was supposed to have a

comfortable club-room, snack-bar and kitchen. This was the first

aircraft design allowing mechanics in-flight access to running engines.

A lot of effort was spent on the K-7 by an armament team lead by

D.I.Grigorov. The military version of aircraft was a real "flying

fortress", which emerged 10 years before the American Boeing B-17.

Defence of Kalinin's giant used as many as 12 gunner positions (8 20mm

cannons and 8 7.62mm machine guns). A special electric cart (running on

strings inside of tail booms) was designed for transportation of

gunners to two tail machine guns. The aircraft had no "blind spots",

and every direction was covered by 3 gunners, which greatly increased

its defence capability.

Bombs were located in wing bomb bays, and bomb bays frames were

included into wing structure. Depending on the required range, bomb

loads varied from 9,900kg to 16,600kg (25,550 - 42,840lb). External

fuel tanks allowed 2,400km flight with 6,000kg bombs.

Other military modifications could carry 112 fully equipped

paratroopers. Opportunities to carry an 8.4 ton tank or other parachute

droppable equipment between main gears was also under study.

The technical project was completed early 1932. In the yard of the

Kharkov Aviation Factory, a full size wooden mock-up of the aircraft

central part was built. The size of aircraft was too big for existing

manufacturing areas, and new assembly hall was built. In November 1932

assembly of a prototype aircraft started which completed just in nine

months.

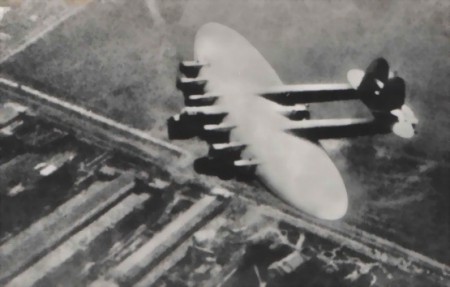

In the early August 1933 the aircraft was taxied on to the runway. Its

test pilot was M.A.Snegirev and the co-pilot was A.N.Giatsinsky. When

all of the engines were started a serious vibration throughout the

aircraft was noted so the affected parts were quickly strengthened. On

August 19 A.M.Snegirev made the first straight flight at 5m altitude.

More troubles were revealed - the elevators were vibrating with

amplitude up to 1m! In a few days the tail of the aircraft was

redesigned - it became a 'biplane' with an additional stabilizing

surface between tail fins. Surfaces from the tail fins were removed,

and those on the tail planes were moved closer to the elevators.

The day before the first flight P.I.Baranov (head of the Major

Management of Aviation Industry) together with test-pilot M.M.Gromov

arrived at Kharkov. At 6 a.m. August 21, 1933 K-7 was 'on the start'

with running engines. The weather was fair despite some light clouds.

Seven crew members took their positions and, as usual, at the last

moment, the co-pilot's seat was occupied by Kalinin himself.

After few taxis, the plane took off smoothly. As A.M.Snegirev said

later, 'the aircraft was very responsive. It was easy to control. Hard

to believe, but you just pull the yoke - and machine responds'.

The K-7 made a circle over Kharkiv, and safely landed on the factory

airstrip.

In the next flights it became clear, that vertical vibration was gone

with the new tail design, but vibration was still present in horizontal

surfaces. M.A.Snegirev, employing his experience as a test pilot, found

a way to suppress it by changing the engines power settings. Continuous

tests revealed fair flying characteristics. The last factory test

flight was scheduled for November 20, and the plane then had to be

flown to Moscow. It was planned to measure the maximum ground level

speed. This flight (10th one) was completed successfully, but the

ground team made a mistake which spoiled the measurements.

The next attempt was planned for November 21. The K-7 now had over 5

hours of flight time. The flight plan included approaching the

'measured kilometre' at an altitude of 1000m, then diving the aircraft

to 100m and exceeding the VNE.

At 2p.m. the K-7 took off with 20 crew members on board. Here is the

story of D.A.Chebyshev, one of ground engineers who participated in the

tests : "As scheduled, K-7 flew over us and the pilot saw that we were

ready for measurements. The aircraft made a turn, accelerated and

started the approach. At about 3 to 4kms from us it made a sudden dive

from 300-400M at full speed. First contact with the ground knocked away

the landing gear. The aircraft bounced and with the engines running it

hit the ground again. A fire started..."

What was recalled by one of the five surviving crew members,

P.I.Semerenko : "Approaching the 'measured kilometre' Snegirev gave

full throttle. The tail booms vibration increased. I counted 15-20

major shudders. Suddenly, to the noise of running engines was added the

sound of the left tail boom lower tube braking apart. Displaced tube

edges locked the elevators, and the K-7 was not able to get out of the

dive. Near the surface the aircraft went into a left pitch. I was

waiting for the end. Controls were still locked still dead. Smash..."

Technicians and designers suffered the destruction of their creation

and death of 15 crew members. K.A.Kalinin was ill for two months

because of heart problems. Despite this catastrophe the team did not

lose their confidence in the design. To investigate the causes of the

crash a committee was formed which included some of the most prominent

aviation experts of the country. It was concluded that the destructive

vibration was caused by the surfaces during some power settings of the

seventh engine. There was no hard evidence to prove this conclusion. A

few years later M.V.Keldysh found the reason for the crash and found a

solution to fight the flutter - weight balancing of elevators. But it

was too late...

After obtaining expert reports, revealing no mistakes in aircraft

design, the head of GUAP ordered Kalinin to start urgent production of

two new (passenger and military) K-7's with scheduled roll-out in the

beginning of 1935. Production was assigned to new base - The Voronezh

Aviation Factory.

Changed views in the country's aviation leadership on production of

heavy aircraft did not allow the team to complete development of K-7.

Both planes were 'preserved', one of them half-built. Kalinin tried to

prove necessity of this aircraft type but failed to win over the

opposition to his project.

|