|

|

methods of reducing

induced drag

Induced drag is caused by the generation of lift. It is created by the

vortices at the tip of an aircraft's wing. The magnitude of induced drag

depends on the amount of lift being generated by the wing and on the shape

and size of the wing. Long, thin (chord wise) wings have low induced drag;

short wings with a large chord have high induced drag.

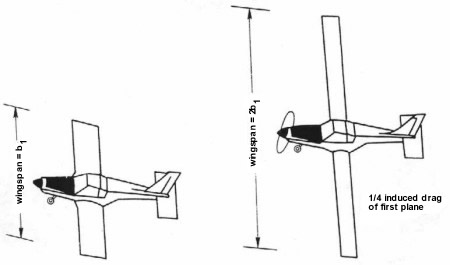

This

figure illustrates the wing-span effect on induced drag for airplanes

having same wing area, same lift coefficient, and same dynamic pressure.

How can

the induced drag be reduced? One may (1) increase the span efficiency

factor to as close to e = 1 as possible, (2) increase the wing span b (or

aspect ratio AR), and (3) increase the free-stream velocity V¥. Induced

drag is a small component at high speeds (cruising flight) and relatively

unimportant since it constitutes only about 5 to 15 percent of the total

drag at those speeds. But at low speeds (takeoff or landing), it is a

considerable component since it accounts for up to 70 percent of the total

drag.

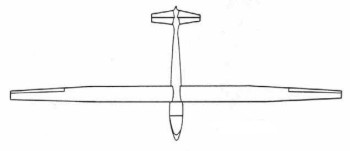

High

aspect-ratio wing

The

efficiency factor e and wing span are physical factors that may be

controlled by proper design. A plane with a longer span wing (higher

aspect ratio) has less induced drag and, therefore, greater efficiency.

But structural considerations become a dominant factor. A very thin long

wing requires a large structural weight to support it, and there comes a

point where the disadvantage of increasing structural weight needed to

support the increased wing span counteracts the advantage of decreased

drag due to smaller vortex effects. An aircraft with a compromise aspect

ratio, and which also considers factors such as fuel capacity, control

characteristics, size allowances, and numerous other factors, would give

the optimum performance. A survey of airplane categories shows sailplanes

with an aspect ratio of 15 or more, single-engine light airplanes with an

aspect ratio of about 6, and supersonic fighter airplanes with an aspect

ratio of about 2.

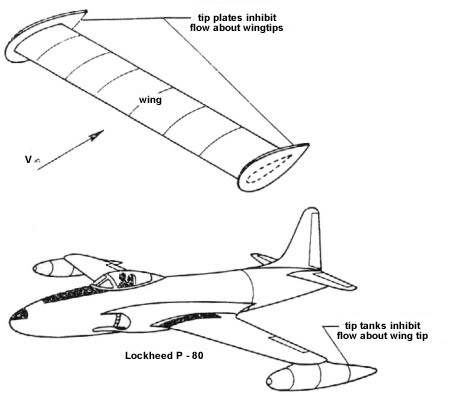

Tip

plates and tip tanks

An

interesting way of reducing induced drag is by the use of tip plates or

tip tanks. This arrangement tends to inhibit the formation of tip

vortices. Tip plates have the same physical effect as an increase in wing

span (or aspect ratio). Normally, these are not used since there are other

more valuable drag reduction methods.

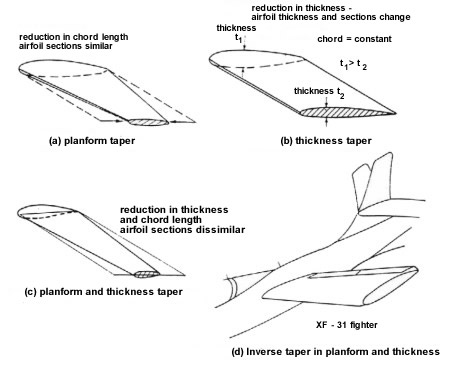

For a general wing, the airfoil sections may vary in three distinct ways

along the wing. First, the size or chord length may change; second, the

shape of the airfoil section may change as one moves along the wing, and

lastly, the angles of attack of the airfoil sections may change along the

wing.

Planform and thickness taper

Planform taper is the reduction of the chord length and thickness as one

proceeds from the root (near the fuselage) to the tip section (at the wing

tip) so that the airfoil sections also remain geometrically similar. (A

planform is the shape of the wing as one looks down on it from above.)

Thickness taper is the reduction of the airfoil's thickness as one

proceeds from the root section (the part of the wing closest to the

fuselage) to the tip section. This reduction results in thinner airfoil

sections at the wing tip. The chord remains constant. One notable

exception to this normal taper was the XF-91 fighter, which has inverse

taper in planform and thickness so that the wing tips were thicker and

wider than the inboard stations.

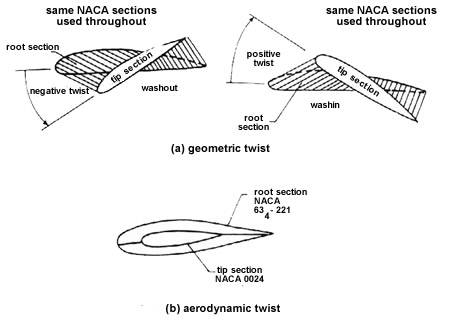

Geometric and aerodynamic twist

Wings are given twist so that the angle of attack varies along the span. A

decrease in angle of attack toward the wing tip is called washout whereas

an increase in angle of attack toward the wing tip is called wash-in.

Geometric twist represents a geometric method of changing the lift

distribution, whereas aerodynamic twist changes lift by using different

airfoil sections along the span—an aerodynamic method of changing the lift

distribution in a span wise manner. To give minimum induced drag, the span

wise efficiency factor e should be as close to 1 as possible. This is the

case of an elliptic span wise lift distribution. A number of methods are

available to modify the span wise distribution of lift. They include (1)

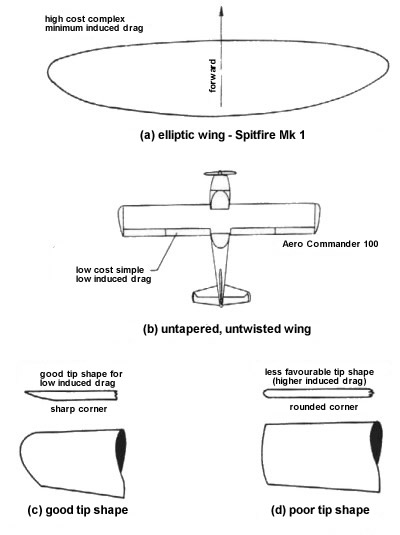

planform taper to obtain an elliptic planform, used for the Spitfire wing,

which was remarkably elliptic; (2) a geometric twist and/or aerodynamic

twist to obtain elliptic lift distribution; or (3) a combination of all of

these methods.

Reduction of induced drag. A square-tipped rectangular wing is almost as

efficient as the elliptic wing

An elliptical planform is hard to manufacture and is costly. From the

point of view of construction, the best type of wing is the un-tapered,

untwisted wing. This is often used by light plane manufacturers.

Surprisingly, data indicates that a square-tipped rectangular wing is very

nearly as efficient as the elliptic wing, so that the gains in reduced

induced drag may be insignificant. This result may be traced to the fact

that, for a real wing, the lift distribution falls off to zero at the wing

tips and approximates an elliptical distribution.

The wing-tip shape, being at the point where the tip vortices are

produced, appears to be of more importance in minimizing tip vortex

formation and thus minimizing induced drag. Taper and twist are perhaps of

greater importance in dealing with the problem of stalling.

|

|