the fuselage structure

The word fuselage is based on the French

word fuseler, which means "to streamline." The fuselage must be strong and

streamlined since it must withstand the forces that are created in flight. It

houses the flight crew, passengers, and cargo.

Fuselages are classified according

to the arrangement of their force-resisting structure. The types of fuselages we

will study are the truss and the semi-monocoque. Five types of stress act on an

aircraft in flight: tension, compression, bending, shear, and torsion. Let's

look at each one individually (figures 1-2).

Tension

Tension is the stress which tends to pull things apart.

When you try to break a length of rope, you exert a type of stress which is

called tension. (see figure 1-2a)

fig 1 - 2a tension stress

Compression

Compression is the opposite of tension. It is the

stress which tends to push materials together. When you grasp a football at both

ends and push, the ball is subject to compression. The landing gear struts of an

aircraft are also subject to compression.

Bending

This type of stress combines tension and

compression. You put a bending stress on a bar when you grasp it with both

hands and push the ends together or when you bend a paper clip. The wing spars

(interior structural members) are subjected to bending while the aircraft is in

flight. The lower side of the spar is subjected to tension, while the upper side

is subjected to compression. Obviously, some materials will break before they

bend and often are unacceptable for aircraft construction. (see figure 1-2c)

fig 1 - 2 c bending stress

Shear

Shear stress is caused by forces tending to slip or

slide one part of a material in respect to another part. This is the stress

that is placed on a piece of wood clamped in a vice and you Chip away at it with

a hammer and chisel. This type of stress is also exerted when two pieces of

metal, bolted together, are pulled apart by sliding one over the other or when

you sharpen a pencil with a knife. The rivets in an aircraft are intended to

carry only shear. Bolts, as a rule, carry only shear, but sometimes they carry

both shear and tension. (see figure 1-2d)

1 - 2d shear stress

Torsion

Torsion is the stress which tends to distort by

twisting. You produce a torsional force when you tighten a nut on a bolt.

The aircraft engine exerts a torsional force on the crankshaft or turbine

axis.

All the members (or major portions) of an aircraft

are subjected to one or more of these stresses. Sometimes a member has alternate

stresses, such as compression one instant and tension the next. Some members can

carry only one type of stress. Wire and cables, for example, normally carry only

tension. (see figure 1-2e)

fig 1 - 2e torsional stress

traditional

construction

Since any member is stronger in

compression or tension than in bending, members carry end loads better than side

loads. In order to do this, designers arrange the members in the form of a

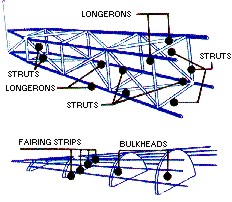

truss, or rigid framework (see figure 1-3). In order for a truss to be

rigid, it must be composed entirely of triangles. When the load on a truss acts

in one direction, every alternate member carries tension while the other members

carry compression. When the load is reversed, the members which were carrying

compression now are subjected to tension and those which were carrying tension

are under compression. The truss itself consists of a welded tubular steel

structure with longerons (horizontal members) and diagonal braces. These

features make it rigid, strong, and light.

fig 1- 3 truss-type fuselage structure

The truss is covered with a

metal or fabric cover so that less drag will be generated. To produce a smooth

surface, the fabric cover is put on fairing strips, which are thin flat strips

of wood or metal. These fairing strips run the length of the fuselage in line

with the direction of flight.

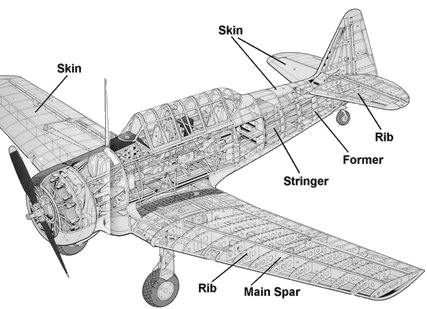

Semi-monocoque

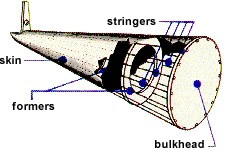

The semi-monocoque is the most often

used construction for modern, high-performance aircraft. Semi-monocoque

literally means half a single shell. Here, internal braces as well as the skin

itself carry the stress (see figure 1-4). The internal braces include

longitudinal (lengthwise) members called stringers and vertical bulkhead.

The semi-monocoque structure is

easier to streamline than the truss structure. Since the skin of the

semi-monocoque structure must carry much of the fuselage's strength, it will be

thicker in some places than at other places. In other words, it will be thicker

at those points where the stress on it is the greatest.

fig 1- 4 semi-monocoque - type fuselage structure

Some aircraft use a

combination of construction methods. The superb Mooney range of four seat

aircraft, for instance, use a steel tube truss frame around the passenger

compartment with semi-monocoque behind.

monocoque construction

Many modern light aircraft are

constructed using composite (glass fibre) materials. This type of construction

is effectively monocoque and is extremely strong. Extra rigidity can be achieved

by using glass foam sandwich construction.

the Glasair is a typical example of a sandwich composite monocoque design

|