landing gear

Landplanes are fitted with either a nose wheel or

tailwheel. The landing gear not only has to support the

aircraft on the ground but must be capable of

withstanding the considerable stresses and shock

loadings experienced during landing. The gear is always

sprung. This can be by the use of spring metal, rubber

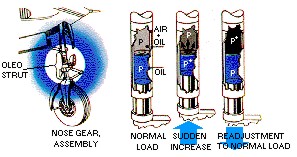

or by oleo. An oleo is in effect a spring and shock

absorber combined.

oleo construction

Most modern aircraft have

are fitted with a nosewheel (tricycle). Earlier designs

are most likely to have a tailwheel (taildragger).

tricycle

gear

tricycle gear

spring metal

landing gear of a fixed undercarriage

Nosewheel airplanes have the "third" wheel in

front of the main landing gear (i.e., under the

nose) as pictured below. Nose-wheel airplanes have

much better handling (due to less airplane behind

the pivot point) and visibility characteristics

while taxiing. Almost all new airplanes are

nose-wheel design. It is most important that the

pilot does not land the aircraft on the nose wheel. This

is called a ' wheelbarrow ' and often results in serious

damage.

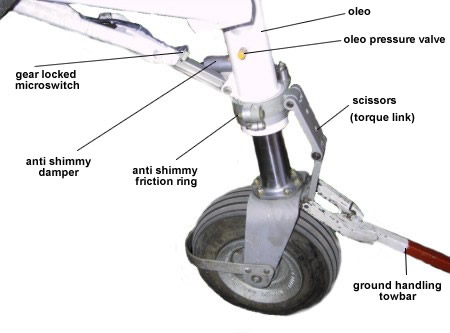

The nose wheel is usually dampened with a shock absorber

or friction ring to prevent shimmy.

click here for shimmy animation.

A torque link is also fitted to maintain

correct nose-wheel alignment. Braking is usually

controlled from the tops of the rudder pedals, and a

separate parking brake is often fitted.

Most light aircraft have

steering nose wheels. When on the ground a linkage is

actuated between the rudder pedals and the nose wheel.

This disconnects automatically once that aircraft

leaves the ground. A small number of aircraft are fitted

with castoring nose wheels. Steering is effected

below rudder authority by the use of the differential

brakes on the main wheels. An example of an aircraft

with a castoring nose wheel is the Grumman Tiger series.

Many homebuilt aircraft are also similarly equipped.

castoring nose gear of

pilotfriend editor's retractable Glasair

Main Gear

typical light aircraft oleo main gear

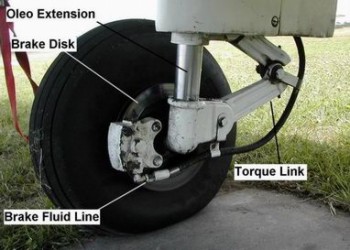

Brakes are usually of the disc type and when

used differentially may be used to reduce turning

circles.

Creep marks are painted on

the tyre and wheel rim so that the pilot can check that

the tyre is not moving on the rim. A maximum of 1/4" is

permitted.

Tailwheel

These

airplanes have the "third" wheel under

the tail. Taildragger aircraft can land on much

rougher terrain and, consequently, are used by

bush pilots. In a tailwheel airplane, this gear

supports the weight of the rear portion of the

airplane. They are harder to control, (imagine

driving a rear steering dumper truck at high speed) and extra

training is required to handle them.

tailwheel retractable. The beautiful Globe Swift

monowheels with outriggers

A small number of

aircraft use a single central landing wheel and are

laterally supported by outriggers. Example are the

U2 spy plane and the homebuilt Europa. Ground

handling is not all that it could be with this

configuration.

the now defunct

Europa

Retractable

landing gear

Retracting the gear

reduces drag and increases airspeed without

additional power. The landing gear normally

retracts into the wing or fuselage through an

opening which may be covered by doors after the

gear is retracted. The smooth door will provide

for the unrestricted flow of air across the

opening that houses the gear. The retraction or

extension of the landing gear is accomplished

either electrically or hydraulically by landing

gear controls from within the cockpit. Warning

indicators are usually provided in the cockpit to

indicate whether the wheels are extended and

locked, or retracted. In nearly all airplanes

equipped with retractable landing gear, a system

is provided for emergency gear extension in the

event landing gear mechanisms fail to lower the

gear. The pilot operating manual will specify the

maximum speed at which the gear can be lowered.

retractable ('complex') aircraft in flight

|