primary

flight controls

These consist of the flight control surfaces and

the engine power management (unless you are flying

a glider that is!).

control

activation

In light

aircraft the control surfaces mentioned

above are moved by the power of the pilot's

muscles. Each control surface is connected

directly to the control column or rudder

pedals with a series of cables and pulleys

or rods.

In such a control system the control column

can move the control surface, but the

control surface can also move the column.

This is called a reversible control.

In large aircraft the pilot requires

assistance in moving the controls.

Assistance may be provided by electrical

motors or hydraulic jacks. When such a

system is employed the controls become

irreversible.

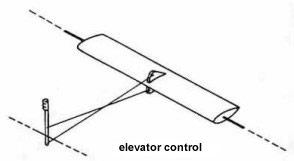

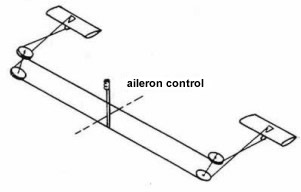

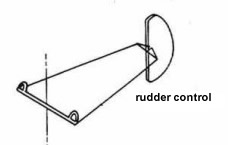

simple controls

A simple basic control system

as operated by a pilot

A

simple mechanical cable operated system as you will find on aircraft such

as the Cessna C152. The cables in some aircraft are replaced by rods.

The control column can be moved by raising and lowering the elevator

boosted control system

This is a simplified boost

system. When the pilot moves the column, tension in the cable or rod also

opens a valve letting pressure from a hydraulic or pneumatic pump expand a

slave cylinder that assists moving the control. The control column can be moved by raising and lowering the elevator

but a considerably more force is required.

fly-by-wire system

There is no mechanical

connection between the control column and the flight surface in a

'fly-by-wire' system. There is a sensor on the control column which

transmits the column's position to an actuator. The actuator then moves

the control surface to a position which matches the column's deflection.

This system is not reversible. (The control column will not be moved by

moving the control surface). The system is much lighter than the boosted

system and is used on all large aircraft nowadays.

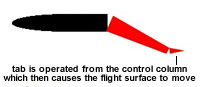

Tab Control

Systems

In the early

days of large aircraft many designers

avoided the need to provide boosted

controls, as described above, by using tab

activated controls. The DC-9 for example

uses tab actuated controls. In a tab

controlled system the pilot moves only a

small actuating tab on the larger control

surface. The force generated by the tab then

moves the main control. This is of course

the same way trim tabs work. Therefore, you

can think of this system as being like trim

tabs if they were connected to the control

wheel instead of a separate control wheel.

Note that in a tab controlled system there

is no direct connection between the control

column and the control surface.

servo and anti-servo tabs

Another way of changing the amount of force the pilot

must apply to the control column is through servo and anti-servo

tabs. In this system the control column is directly

connected to the control surface (just like a C-172) but a tab is

geared to the movement of the control surface so that it either

assists the movement of the control, or counters the movement of the

control. Thus, the controls can be made to feel heavier or lighter

than they would otherwise.

|

servo tab

|

anti servo tab

|

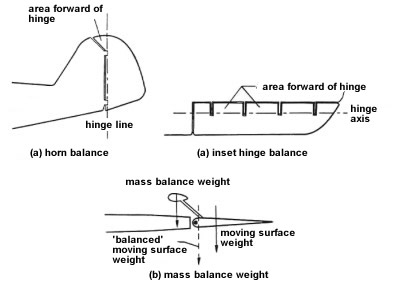

Control Horns

On an aircraft with

reversible controls

the pilot must apply

a force to the

control column

sufficient to keep

the the control

surface deflected in

the air stream. To

assist the pilot the

aircraft design will

usually provide a

control horn, such

as the one shown to

the right. The horn

is simply an

extension to the

control surface

which projects ahead

of the hinge. The

air striking the

horn assists the

pilot to deflect the

control surface.

Horns are usually

provided on

elevators and

rudders. Ailerons

usually do not

require horns.

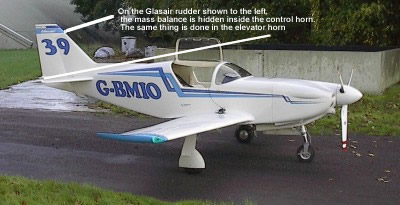

Mass Balance

When a control is

deflected a low

pressure area forms

on the cambered

side. This tends to

pull the control

back into alignment

with the wing,

stabilizer or fin as

the case may be.

However, the control

surface has mass and

therefore momentum.

If the centre of

gravity of the

control surface is

behind the hinge,

the control tends to

overshoot the point

of alignment. The

result is a tendency

for the control to

flutter. Flutter

could become

sufficiently severe

that the aircraft

could break up in

flight.

To solve the above

problem the control

must be balanced, so

that its centre of

gravity is in line

with the hinge.

click here

to see flutter movie

The exact distribution of weight on a

control surface is very important. For this reason, when a control surface

is repainted, repaired or component parts replaced, it is essential to

check for proper balance and have it rebalanced if necessary. To do this,

the control surface is removed, placed in a jig and the position of the

centre of gravity checked against the manufacturer's specifications.

Without any airflow over the control surface, it must balance about its

specified C.G. This is known as static balance. For example, the

aileron of the Bonanza is designed for a static nose heavy balance of 0.2

inch pounds. The C.G. of the aileron is forward of the hinge centreline

causing the control surface to be nose heavy.

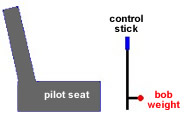

Bob

weights

Bob

weights

are

sometimes

known as

counter

weights.

Their

purpose

is to

change

the

amount

of

control

force

required

to

deflect

the

control

column

under

different

g-loadings.

Normally

the

amount

of force

the

pilot

must

apply to

the

control

column,

assuming

reversible

controls,

varies

with

airspeed

only.

However,

by

installing

a bob

weight

the

aeronautical

engineer

can make

it more

difficult

to pull

on the

control

column

as

g-force

increases. The

purpose

of the

bob

weight

is to

reduce

the

likely

hood the

pilot

will

overstress

the

aircraft.

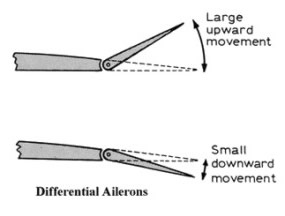

Differential

Ailerons

Differential

ailerons

are

designed

so that

the

up-going

aileron

rises a

greater

angle

than the

down

going

aileron.

When we

use

ailerons

we want

the ship

to roll

only on

its

longitudinal

axis.

The

problem

is that

to raise

a wing

the

aileron

increases

lift on

that

wing

with the

resultant

increase

in drag.

At the

same

time

there

usually

is a

decreased

lift on

the

opposite

wing

with a

decrease

in drag.

The

descending

wing has

less

drag and

moves

forward

while

the

rising

wing has

more

drag and

moves

backwards.

This

produces

a

tendency

to yaw

(turn)

in the

wrong

direction

or into

the

rising

wing and

away

from the

intended

turn

direction.

This

usually

results

in a

nose

high

slip

with the

fuselage

side

presented

to the

relative

wind

with

high

drag.

This is

called

"adverse

yaw" and

is fine

if you

need to

lose

altitude

with

lateral

fuselage

drag as

in a

landing

approach,

but bad

for

beginning

a

coordinated

turn

with the

fuselage

parallel

to the

relative

wind.

To

compensate

for this

problem

and make

flying

easier,

aircraft

are

usually

designed

with one

or a

combination

of a

number

of

methods

to

decrease

adverse

yaw.

The

common

fix for

adverse

yaw is

to

mechanically

produce

differential

aileron

movement

so that

there is

more up

travel

than

down. In

other

planes

the

aileron

is

hinged

towards

the top

of the

wing/aileron

joint so

that a

portion

of the

leading

edge of

the

aileron

sticks

down

into the

slipstream

creating

drag

when the

wing is

descending

to

balance

the

resultant

drag

from the

rising

wing.

Frieze

Ailerons

Frieze

ailerons

are

designed

so that

when the

aileron

is

deflected

upward a

lip

extend

down

into the

air

stream.

As a

result

the

up-going

aileron

produces

more

drag

than the

down

going

aileron.

This

helps

provide

some of

the

force

required

to start

the

aircraft

yawing

in the

desired

direction

of the

turn.

Usually

this is

enough

force to

provide

the

required

turn

moment

but not

enough

to

overcome

aileron

drag.

Therefore,

the

pilot

will

still

need to

use the

rudder

to

coordinate

the turn

when

large

aileron

deflections

are

employed.

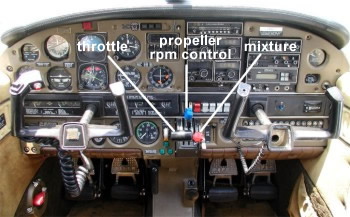

engine management

On

simple

aircraft

on which

student

pilots

usually

begin,

there

are two

controls.

The

throttle,

which is

always

black in

colour,

and the

fuel

mixture

control,

which is

always

red. Vernier

'push

pull'

controls

such as

in the

illustration

below

appear

to be

popular

with

Cessna.

More

power is

applied

if the

vernier

is

pushed

in.

Fuel is

shut off

to the

engine

if the

mixture

control

is

pulled

out. As

simple

aircraft

have

fixed

pitch

propellers,

increase

in

throttle

will

increase

the

RPM

of the

propeller.

For more

information

about

propellers,

see the

propeller

section.

typical

Cessna

152

engine

management

controls

Other

aircraft

are

fitted

with

quadrant

lever

controls,

(Piper

for

example).

Power is

applied

by

pushing

the

lever

FORWARD.

The fuel

supple

to the

engine

is cut

off by

pulling

the

lever

back.

typical

quadrant

engine

management

controls

mixture

This is operated by the red

control. At close to sea level altitudes,

the mixture shown be maintained in the fully rich

position. This should always also be the case when

power setting are used that are more than 75%

available, the the fuel contributes to the cooling

of the engine. Once cruising altitude is reached,

the mixture can be leaned. This results in

considerable fuel savings. As the mixture is leaned,

the exhaust gas temperature increases. The gauge is

marked with a red line, and leaning should never

exceed this. If an exhaust gas temperature gauge is

not fitted the mixture can be adjusted by

observation. As the mixture is leaned, there will be

a small increase in engine RPM, or power in the case

of a complex aircraft. Continued leaning will result

in a decrease in RPM. The mixture should then be

enriched until it is just on the rich side of

maximum RPM.

At airfields of high altitude,

the mixture must be leaned to produce full power on

the ground, prior to take-off.

carburettor heat

While carburettor heat is not a

primary instrument, it is useful to include it in

this chapter. Incredibly many aircraft engines

are still fitted with carburettors, despite the fact

that fuel injection has been generally available

since half way through the last century. These

archaic devices have a nasty habit of freezing up

and preventing the fuel mixture from entering the

engine, which begins to run a tad rough and then

stops, sometimes with fatal results. This will

happen when operating close to the dew point, and

also when the engine is running under reduced power,

such as during a descent. It is up to the pilot to

periodically operate the carburettor (carb) heat control, which

is usually to the right of the throttle and mixture

controls. Carb heat control diverts hot air into the

carburettor from a sleeve around the exhaust system

and which will melt the offending ice. The engine

must ingest the resulting water, so sometimes it

will run rougher than before for a short period.

Carburettors can suffer from a variety of different

icing and this will be looked at later (see aircraft

technical 'induction system').

The carb. heat should always be applied during

descent.

The power to the engine is reduced when carb heat is

applied so it t is good practice to remove it just

before touchdown (say 100 feet) so that full power

is instantly available should a go around become

necessary.

Complex

Aircraft

which

are

fitted

with a

constant

speed

propeller

have a

third

system

which

manages

the RPM

of the

propeller.

This is

always

blue in

colour.

The

throttle

in this

case

just

increases

available

power

and RPM

is

controlled

by the

propeller

control.

There is

an order

in which

these

controls

should

be used

to avoid

a

possible

overspeed

of

propeller.

increase

RPM

Blue

first

Black

second

decrease

RPM

Black

first

Blue

second.

Students

almost

always

begin

flying

in

simple

aircraft.

Further

training

is

required

to

operate

complex

types

such as

the

Piper

Arrow or

Mooney

series.

|