helicopters:

their main components and

controls

with thanks to the

helicopterpage

Rotary Wing

Terminology

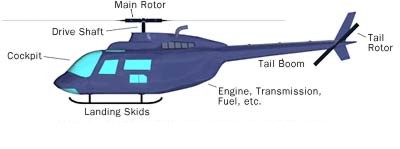

Most helicopters the engine

turns a shaft that connects to an input quill

on the transmission; the main rotor mast comes

straight out of the top of the transmission

and the tailrotor driveshaft connects to an

output quill 90 degrees out from the mast.

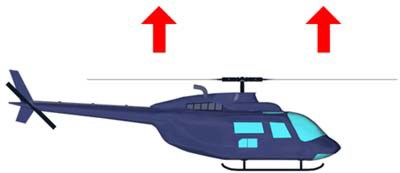

Spinning the rotor which has an aerofoil

section causes

lift, allowing the helicopter to rise

vertically or hover.

Tilting the spinning rotor will cause flight

in the direction of the tilt.

There are many terms

associated with rotary wing flight and it is

important for a student to become familiar

with them to understand the mechanics of rotary wing

flight.

Main Rotor

System

Root: The

inner end of the blade where the rotors

connect to the blade grips.

Root: The

inner end of the blade where the rotors

connect to the blade grips.

Blade

Grips: Large attaching points where the

rotor blade connects to the hub.

Blade

Grips: Large attaching points where the

rotor blade connects to the hub.

Hub: Sits

atop the mast, and connects the rotor blades

to the control tubes.

Hub: Sits

atop the mast, and connects the rotor blades

to the control tubes.

Mast:

Rotating shaft from the transmission, which

connects the rotor blades to the helicopter.

Mast:

Rotating shaft from the transmission, which

connects the rotor blades to the helicopter.

Control

Tubes: Push \ Pull tubes that change the

pitch of the rotor blades.

Control

Tubes: Push \ Pull tubes that change the

pitch of the rotor blades.

Pitch

Change Horn: The armature that converts

control tube movement to blade pitch.

Pitch

Change Horn: The armature that converts

control tube movement to blade pitch.

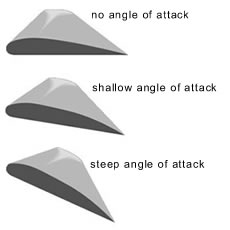

Pitch:

Increased or decreased angle of the rotor

blades to raise, lower, or change the

direction of the rotors thrust force.

Pitch:

Increased or decreased angle of the rotor

blades to raise, lower, or change the

direction of the rotors thrust force.

Jesus Nut:

Is the singular nut that holds the hub onto

the mast. (If it fails, the next person you

see will be Jesus).

Jesus Nut:

Is the singular nut that holds the hub onto

the mast. (If it fails, the next person you

see will be Jesus).

this type of rotor system pivots around the

trunion to allow for blade flapping

Swash plate

The swash plate assembly has two primary

roles:

Under the direction of the collective

control, the swash plate assembly can change

the angle of both blades simultaneously.

Doing this increases or decreases the lift

that the main rotor supplies to the vehicle,

allowing the helicopter to gain or lose

altitude.

Under the direction of the collective

control, the swash plate assembly can change

the angle of both blades simultaneously.

Doing this increases or decreases the lift

that the main rotor supplies to the vehicle,

allowing the helicopter to gain or lose

altitude.

Under the direction of the cyclic

control, the swash plate assembly can change

the angle of the blades individually as they

revolve. This allows the helicopter to move

in any direction around a 360-degree circle,

including forward, backward, left and right.

Under the direction of the cyclic

control, the swash plate assembly can change

the angle of the blades individually as they

revolve. This allows the helicopter to move

in any direction around a 360-degree circle,

including forward, backward, left and right.

The swash plate assembly consists of two

plates -- the fixed and the rotating

swash plates -- shown above in blue and red,

respectively.

The rotating swash plate rotates

with the drive shaft (green) and the rotor's

blades (grey) because of the links (purple)

that connect the rotating plate to the drive

shaft.

The rotating swash plate rotates

with the drive shaft (green) and the rotor's

blades (grey) because of the links (purple)

that connect the rotating plate to the drive

shaft.

The pitch control rods (orange)

allow the rotating swash plate to change the

pitch of the rotor blades.

The pitch control rods (orange)

allow the rotating swash plate to change the

pitch of the rotor blades.

The angle of the fixed swash plate

is changed by the control rods (yellow)

attached to the fixed swash plate.

The angle of the fixed swash plate

is changed by the control rods (yellow)

attached to the fixed swash plate.

The fixed plate's control rods are

affected by the pilot's input to the cyclic and collective controls.

The fixed plate's control rods are

affected by the pilot's input to the cyclic and collective controls.

The fixed and rotating swash plates are

connected with a set of bearings

between the two plates. These bearings allow

the rotating swash plate to spin on top of

the fixed swash plate.

The fixed and rotating swash plates are

connected with a set of bearings

between the two plates. These bearings allow

the rotating swash plate to spin on top of

the fixed swash plate.

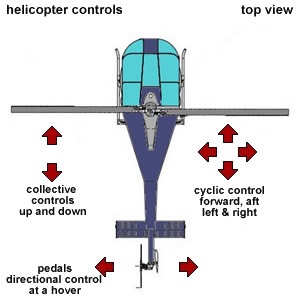

Controls

Collective: The

up and down control. It puts a collective

control input into the rotor system, meaning

that it puts either "all up", or "all down"

control inputs in at one time through the

swash plate. It is operated by the stick on

the left side of the seat, called the

collective pitch control. It is operated by

the pilots left hand.

Collective: The

up and down control. It puts a collective

control input into the rotor system, meaning

that it puts either "all up", or "all down"

control inputs in at one time through the

swash plate. It is operated by the stick on

the left side of the seat, called the

collective pitch control. It is operated by

the pilots left hand.

The collective

lets you change the angle of attack of the

main rotor simultaneously on both blades.

Cyclic: The

left and right, forward and aft control. It

puts in one control input into the rotor

system at a time through the swash plate. It

is also known as the "Stick". It comes out

of the centre of the floor of the cockpit,

and sits between the pilots legs. It is

operated by the pilots right hand.

Cyclic: The

left and right, forward and aft control. It

puts in one control input into the rotor

system at a time through the swash plate. It

is also known as the "Stick". It comes out

of the centre of the floor of the cockpit,

and sits between the pilots legs. It is

operated by the pilots right hand.

The cyclic changes the angle

of attack of the main rotor's wings unevenly

by tilting the swash plate assembly. On one

side of the helicopter, the angle of attack

(and therefore the lift) is greater.

Pedals: These

are not rudder pedals, although they are in

the same place as rudder pedals on an

airplane. A single rotor helicopter has no

real rudder. It has instead, an anti-torque

rotor (Also known as a tail rotor), which is

responsible for directional control at a

hover, and aircraft trim in forward flight.

The pedals are operated by the pilots feet,

just like airplane rudder pedals are. Tandem

rotor helicopters also have these pedals,

but they operate both main rotor systems for

directional control at a hover.

Pedals: These

are not rudder pedals, although they are in

the same place as rudder pedals on an

airplane. A single rotor helicopter has no

real rudder. It has instead, an anti-torque

rotor (Also known as a tail rotor), which is

responsible for directional control at a

hover, and aircraft trim in forward flight.

The pedals are operated by the pilots feet,

just like airplane rudder pedals are. Tandem

rotor helicopters also have these pedals,

but they operate both main rotor systems for

directional control at a hover.

The Tail Rotor

The tail

rotor is very important. If you spin a rotor

using an engine, the rotor will rotate, but

the engine and the helicopter will try to

rotate in the opposite direction. This is

called TORQUE REACTION

The tail rotor is used like

a small propeller, to pull against torque

reaction and hold the helicopter straight.

By applying more or less

pitch (angle) to the tail rotor blades it can

be used to make the helicopter turn left or

right, becoming a rudder. The tail rotor is

connected to the main rotor through a gearbox.

When using the tail rotor trying to compensate

the torque, the result is an excess of force

in the direction for which the tail rotor is

meant to compensate, which will tend to make

the helicopter drift sideways.

Pilots tend to compensate by applying a little

cyclic pitch, but designers also help the

situation by setting up the control rigging to

compensate.

The result is that many helicopters tend to

lean to one side in the hover and often touch

down consistently on one wheel first.

On the other hand if you observe a hovering

helicopter head-on you will often note that

the rotor is slightly tilted. All this is a

manifestation of the drift phenomenon.

This picture

illustrates how the helicopter moves when

using the appropriate controls. Up and Down

movements are controlled by the "Collective".

Side to Side and Forward and Back motions are

controlled by the "Cyclic". Lateral control

(Also called directional control or "Yaw") is

achieved by using the "Foot Pedals".

Dissymmetry of

lift

One

cannot begin to talk about the mechanics of

helicopters until the problems

associated with rotary wing aerodynamics are

understood. When

the first rotary wing pioneers started trying

to make a helicopter fly, they noticed a

strange problem.

The helicopters

rotor system would generally work just fine

until one of two things happened: Either the

aircraft began to move in any given direction,

or it experienced any sort of wind introduced

into the main rotor system. Upon either of

these events, the rotor system would become

unstable, and the resultant crash would

usually take the life of the brave soul at the

controls. The question then was; Why does this

happen? The answer is what we refer to today

as "Dissymmetry of lift".

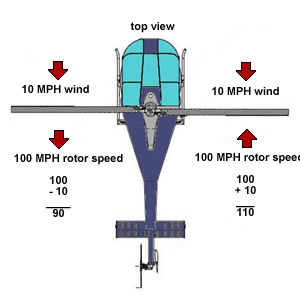

What "Dis-Symmetry

of lift" means is, when the rotor system is

experiencing the same conditions all around

the perimeter of the rotors arc, all things

are equal, and the system is in balance. Once

the system experiences a differential in wind

speed from any angle, it becomes unbalanced,

and begins to rotate. Take for instance

forward flight. Imagine a two bladed rotor

system spinning at 100 MPH.

The blade moving

toward the forward end of the aircraft is

going 100 MPH forward, and the blade moving

toward the back of the aircraft is travelling

at 100 MPH in the other direction. This is

just fine when the aircraft is not moving or

is in a no wind condition. It is experiencing

100 MPH of wind in all directions, so it is

totally in balance. Once the aircraft moves

forward, it begins to change this balance. If

we travel 10 MPH forward, then the forward

moving, or advancing rotor blade, is

experiencing 110 MPH of wind speed, and the

rearward, or retreating blade, is experiencing

only 90 MPH of wind speed.

When this happens,

we get an unbalanced condition, and the

advancing blade experiencing more lift wants

to climb, while the retreating blade

experiences less lift and wants to drop. This

is where we get the term "Dis-Symmetry of

lift". The lift is not symmetrical around the

entire rotor system.

How do we

compensate for this situation? We compensate

by allowing the rotor to flap. By allowing the

advancing blade to flap upward, and the

retreating blade to flap downward, it changes

the angle of incidence on both rotor blades

which balances out the entire rotor system. As

you can see in this simple graphic, there are

a few ways to allow for blade flapping.

One is

to allow the blades to flap on hinges

(Articulated rotor system). Another way is to

have the whole hub swing up and down around an

internal bearing called a trunion (Semi-rigid

rotor system). Unfortunately, we can not

compensate completely for dis-symmetry of lift

by using blade flapping. Once the aircraft

gets to a certain airspeed, and the rotor had

flapped as much as it possibly can, then

"Retreating blade stall" may be experienced.

In retreating blade stall, the retreating

blade can no longer compensate for dis-symmetry

of lift, and the outer portions of the blade

will "Stall".

This situation,

when not immediately recognized can cause a

severe loss of aircraft controllability. This

is a major airspeed limiting factor for

helicopters. For many years, aeronautical

engineers have tried to figure ways to

eliminate this problem and increase the

forward airspeed for single rotor helicopters.

Although many breakthroughs have been made,

the manufacturers of single rotor helicopters

are usually not willing to change the entire

design on their products because of the extra

costs involved for little airspeed payoff.

Most have resigned themselves to slower

airspeeds for their aircraft, at a lower cost

and less maintenance.

The

main rotor hub, where the rotor's drive shaft

and blades connect, has to be extremely strong

as well as highly adjustable. The swash plate

assembly is the component that provides the

adjustability.

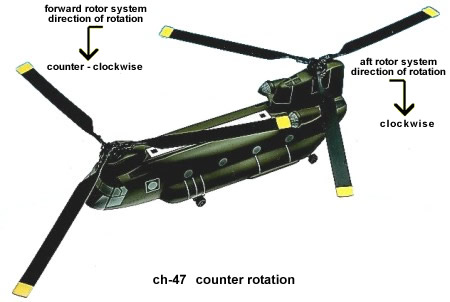

Counter-Rotation Vs Contra-Rotation

One thing that

people often get confused with is the

difference between "Contra-Rotation" and

"Counter-Rotation". The terms are used

incorrectly more than you could possibly

imagine in books, manuals, and on web sites. I

wanted to take this opportunity to clear up

the difference between the two.

As you can see by

the first diagram, "Counter-Rotation" is where

there are two individual shafts driving two

propellers or rotors in different directions.

Although we have chosen to show this example

on a CH-47 Chinook from above, it is

exactly the same on a twin engine airplane

that has one propeller turning one way, and

one turning the opposite way (Like on a P-38

"Lightning"). Sometimes, as in the case of the

CH-47, the rotors will mesh, so the

synchronization of the systems is crucial.

On

airplanes, where the propellers do not mesh it

is not as critical that the systems are in

synch. In an airplane, if the systems are out

of synch, it can put undue stress on the

airframe, and cause harmonic vibrations

throughout the airframe. You can usually hear

an airplane that has the engines out of synch,

as it will make a varying strobe like sound.

Each propeller in

an airplane counter rotating system has its

own set of mechanical controls to vary the

pitch of the blades. Often it is a hydraulic

system, but in some cases (Like the P-38),

other means can be employed such as electric

power. In a helicopter, both rotors are

manipulated by one set of controls for the

pilot.

contra-rotation

"Contra-Rotation"

is where the propellers or rotors are mounted

"Co-Axially", meaning one in front of (or on

top of) the other on the same axis. Usually,

the drive mechanism is a single source, but

the direction of rotation is spilt by a

gearbox to drive the two systems in opposite

directions. This is usually done to reduce the

"P" factor or "torque" in a turn. While we

have chosen to show this example in the form

of a Royal Navy Fairey Gannet, it also

applies to helicopters (Like on the Soviet

"Hokum").

The main use for this on a

helicopter is that it negates the need for a tailrotor (Anti-torque rotor) to maintain

directional control at a hover. It also tends

to relieve some of the effects of retreating

blade stall as both sides of the aircraft have

advancing rotor blades.

In an airplane,

one set of controls will adjust the pitch of

both propellers at the same time. Usually, it

is done by varying hydraulic pressure in the

propeller hubs. In a helicopter, both rotors

are manipulated by a single set of pilot

controls as well, but two sets of control

tubes working off of two alternately rotating

swashplates are needed to adjust the rotors at

the individual hub.

The Forces At

Work

There are many

forces at work when a helicopter flies

including lift, drag, gravity, and thrust.

However there are specific

conditions experienced exclusively in rotary

wing flight.

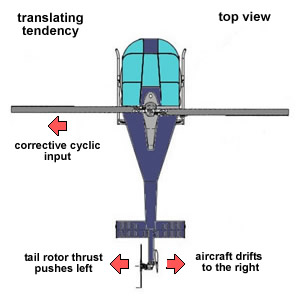

Translating

Tendency

Translating

tendency is defined by the textbooks as: The

tendency for a single rotor helicopter to

drift laterally, due to tail rotor thrust. One

may not think about how much thrust is

produced by the tail rotor, but we must

remember that the tail rotor has a 6 to 1

rotational ratio to the main rotor system.

It actually spins

6 times faster than the main rotor, so it can

compensate for the torque of the main rotor

without the need for a massive tail rotor

span. The thrust it produces tends to push the

aircraft sideways at a hover. We compensate

for this by adding left cyclic control inputs

(On American Helicopters, the opposite in

foreign manufactured aircraft, because their

rotor systems turn the opposite way from

ours). This makes the helicopter hang left

skid, or wheel, low at a hover. If you ever

see an American helicopter hovering, you may

notice this left side low condition. If you

ask a helicopter pilot how he is doing, and he

answers, " Left skid low", that means

everything is normal.

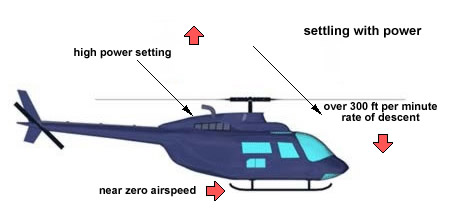

Settling With Power

Settling with power can be a dangerous

condition that any pilot may face, and if he

or she is not on their toes, it may cause a

serious uncontrollable situation. Settling

with power is basically when the helicopter

settles into the rotor wash produced by its

own main rotor system. It requires 3 key

elements to occur, and these conditions should

be avoided in combination with one another.

These are: A near

zero airspeed, up to 100% power applied, and a

better than 300 foot per minute rate of

descent. Once you have all of these situations

in occurrence, the aircraft will settle in its

own down wash from the rotor system. The only

way to recover is to gain forward airspeed and

allow the rotor system to fly into "Clean

air". Once the rotor system is clear of the

rotor-wash, it will become efficient again,

and the settling with power conditions will

cease to exist.

This can become a

real problem at an out of ground effect hover

(Above 10 feet from the ground), and during

landings.

'Settling With Power' or 'Settling in your own

downwash' is a dangerous situation that any

rotary wing machine can experience.

The term "Vortex Ring State" is used to

describe the actual swirling of the air within

the rotor system itself that causes "Settling

With Power".

Vortex Ring State can begin to occur when you

have 300 Feet per minute (FPM) as a rate of

descent.

Pilots

need to be aware of the situation and avoid it

at all costs.

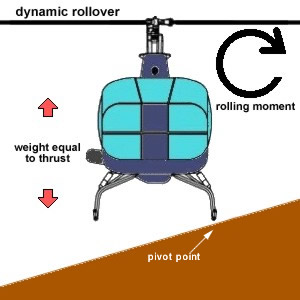

Dynamic

Rollover

Another

dangerous condition for a helicopter pilot to

experience is called dynamic rollover. It is

again, where you have a series of conditions

that combine to make a dangerous situation.

Once again, 3 key elements make up this

hazardous condition. They are: A pivot point,

a rolling moment, and weight equal to thrust

at some time during the manoeuvre. What

actually happens is that the helicopter, which

is still on the ground, will start to roll

over on its side using one skid, or wheel, as

the pivot point.

Once the aircraft

starts to roll, a downward collective movement

is the only thing that will stop the forces in

action from flipping the aircraft on its side.

By reducing the collective, the thrust to

weight ratio decreases, which allows the

aircraft to settle back down in a level

attitude. If this is done on sideward sloping

terrain, a collective reduction performed too

quickly can cause the aircraft to roll over on

the other side, down the slope. Care must be

exercised when performing slope operations,

but dynamic roll over can occur on the

flattest of surfaces if the pilot becomes

complacent.

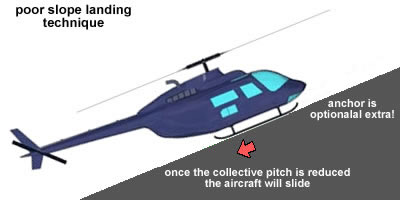

It is normal

practice to tackle a

slope from the side and not from the front or

back because most helicopters

have skid type landing gear with no brakes.

Skid gear will most likely slide down a hill

if the toes or heels of the skids are pointed

up hill once the power is taken away holding

the aircraft in place.

Once that force

is no longer applied, the weight of the

aircraft will get it started sliding and,

depending on the slope, could pick up so much

speed that it crashes severely at the bottom

of the hill. The ones that have wheels

and brakes could slide also depending on the

degree of slope and condition of the ground.

Other reasons not

to attack a slope from the front or back is

that the tail boom may strike the hill before

the skids do (Again, depending on the degree

of the slope) or the rotor system may impact

the hill before the skids do. Usually, if the

standard 8 degrees of slope are used as a

maximum, then a sideward approach to the slope

will have the skids touching before the rotor

system. Care should be used when passengers

depart the aircraft on a slope as they may

walk into the rotor if they go up hill. Always

brief the passengers to leave the aircraft on

the down slope side of the aircraft.

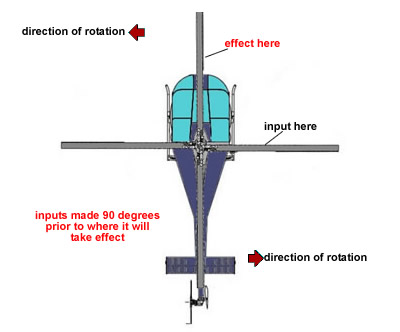

A rotating body acts like a gyroscope and the

forces that act upon the gyroscope require

some adjustment to allow for the rotation

itself. A spinning body will take inputs

placed at one part of the cycle of rotation

and react later in the cycle of rotation. Now

without getting too technical, the main thing

to remember here is that with the rotation

comes some extra planning. If you want a

control input to take effect, you just have to

be a little ahead of where you want it to

happen. In this case, 90 degrees before the

spot where the action you desire is to take

effect is where you have to plan to put it

into the system. Input is placed in one

location and as the blade swings 90 degrees

more in the direction of rotation, the desired

effect will be realized.

|