|

electrical

starters

The increased use in aircraft of batteries and generators for

battery charging has made available current sources of

sufficient capacity to provide adequately for the electrical

requirements of the direct cranking electric type of aircraft

engine starters. The Direct Cranking Electric Starter presents

many advantages which recommend its use in installations,

where convenient engine starting is desired. The starter,

controlled from the cockpit, provides instantaneous and

continuous 'cranking. This feature is desirable in private and

commercial air transport installations, where sufficient

battery capacity is available, as it permits prompt starting

without external assistance. Direct cranking electric starters

are available in capacities for engines rated from 50 to 1500

horsepower.

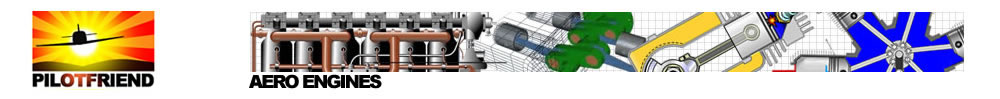

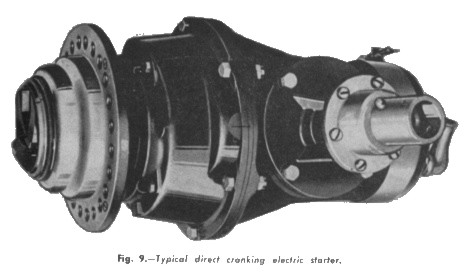

This type of starter consists basically of

an electric motor, a gear reduction and an automatic engaging

and disengaging mechanism, which operates through an

adjustable torque overload release. The engine is cranked

directly by the starter and there is no preliminary storage of

energy as with the inertia type of starter. Therefore, it can

be assumed that for a specific engine under extreme low

temperature conditions, with resultant high cranking torque,

the current consumption will be somewhat higher than would be

the case with an electric inertia starter on the same engine

under similar conditions, because of the direct connection

between the starter motor and the engine during the cranking

period. The direct cranking electric starter is intended for

use on large commercial transports and privately owned

airplanes, which are normally stored in hangars and are not

subject to cold weather starting. The use of external

batteries in the form of a dolly are recommended for cranking

engines of large aircraft transports equipped with direct

cranking electric starters in order to save the airplane

batteries.

Direct Cranking Starters

The direct cranking electric starters are

normally furnished less hand crank mechanism with the

exception of large capacity units which are supplied with a

hand crank mechanism if required. The starters are designed

for operation from a 12 or 24 volt battery source. Upon the

application of current to the motor terminals, the torque of

the motor is transmitted through a gear reduction unit to the

adjustable torque overload release, which in turn actuates a

splined screw shaft which moves the starter jaw axially

outward into engagement with the engine cranking member before

the starter jaw begins to rotate. Thus, complete engagement is

effected before cranking commences. The torque overload

release in the form of a multiple disc clutch is adjusted to a

predetermined value so as to deliver sufficient, yet not

excessive cranking torque to the engine. In case of engine

back-fire, the clutch slips, preventing damage to the engine

and starter. With this type of starter, engine cranking is

continuous but at a lower speed than that obtained with the

inertia type of starter. The current draw of the direct

cranking electric starter varies directly with engine size and

torque characteristics. It will therefore be considerably

higher than that required for the operation of the inertia

type starters.

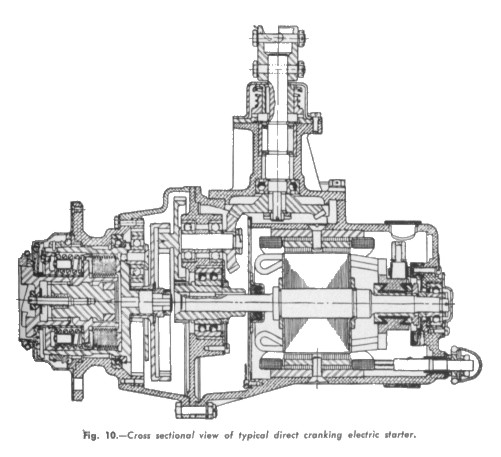

The Combination Direct Cranking Electric

Starter With Integral Hydraulic Feathering Pump

The direct cranking electric starter with

integrally mounted hydraulic feathering pump has been

developed to replace the standard type of direct cranking

electric starter and separately mounted electric motor driven

hydraulic feathering pump for installations utilizing the

Hamilton Standard Hydromatic Propeller. Primarily designed and

developed for use in conjunction with Hamilton Standard

Hydromatic Propellers, the starter pump unit incorporates all

of the features of the conventional direct cranking electric

starter, with the exception that the hand crank mechanism

fitted to starters of this type has been removed and a

hydraulic pump mounted in its place. With this type of

starter, a reversible motor is utilized in order to permit

driving of the hydraulic feathering pump when the starter is

not in operation. The starter pump unit, in addition to

providing a saving in weight due to the elimination of an

additional electric motor and excess line tubing, provides a

compact and light weight installation integral with the power

plant and available for operation as required. The design of

the starter pump unit is such that when used in conjunction

with two solenoid starting relays, battery booster coil and a

suitable control switch, remote control of both starter and

feathering pump is provided. As with the conventional type of

direct cranking electric starter, jaw engagement is automatic

upon closing of the motor circuit. An overrunning clutch,

interposed between the starter and pump provides starter

operation without rotation of the hydraulic pump. The

hydraulic pump, which may be of either the internal or

external gear type, provides a dependable and efficient source

of hydraulic pressure for the feathering and unfeathering of

Hamilton Standard Hydromatic Propellers.

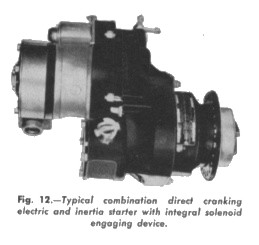

Combination Direct Cranking Electric And

Inertia Starter Wit11 Integral Solenoid Engaging Device

Among the most outstanding recent

developments in aircraft engine starting equipment has been

the combination direct cranking electric and inertia starter,

which incorporates all the features of the hand or combination

hand and electric inertia starters and in addition, provides,

by means of a heavy duty integral accelerating motor,

continuous cranking of the aircraft engine after dissipation

of the flywheel kinetic energy. Thus the energy stored in the

starter flywheel at the initial engagement of the starter and

engine jaws is used to overcome the heavier breakaway torque

after which the lighter load of continuous cranking is assumed

by the electrical system. The result is notably less drain on

the source of electrical energy with greater convenience and

starting ease. Although only available at the present time for

use in conjunction with engines, rated at approximately from

1500 to 1800 horsepower, this starter can be readily modified.

The design of the starter is such, that

when used in conjunction with a separately mounted solenoid

starting relay, battery booster coil and three position

starter control switch, remote control of motor acceleration

and starter jaw engagement is provided. The starter may be

operated as a direct cranking electric starter or as a

combination, direct cranking electric and inertia starter, by

means of the control switch, as required. For cold weather

starting, operation of the unit as a combination direct

cranking electric and inertia starter is recommended, whereas

for warm weather starting or where immediate continuous

cranking is desired, the unit may be operated as a direct

cranking electric starter. For emergency operation when the

source of electrical energy is not sufficient to permit proper

electrical operation as a combination direct cranking electric

and inertia starter, the unit may be operated as an electric

inertia starter, in which case manual engagement of starter

and engine jaws is required. In addition, the unit may be

operated as a hand inertia starter for emergency operation, in

which case it is also necessary to manually engage the starter

and engine jaws. A universal hand crank mechanism is provided

on these starters with provisions for either clock or counter

clock rotation hand cranking. With this type of hand crank

mechanism the position for hand crank take off may be readily

adjusted to facilitate starter installation, available for 12

or 24 volt operation.

|