|

aircraft engine

history

air-cooled aircraft engine

cylinders

by George Genevro

From the Past

Should aircraft engines be

liquid-cooled or air-cooled? This “difference of opinion” is

about a hundred years old and without a doubt the argument

will continue as long as piston engines power the airplanes we

fly. The manner in which the question is stated is misleading,

however, since all waste heat that comes through the structure

of an engine is eventually delivered to the air. In

“liquid-cooled” engines the coolant can be water, ethylene

glycol, a mixture of the two, or one of the many other liquids

that have been tried and found wanting. Its primary purpose is

to carry heat from the cylinder barrel and head to the

radiator through which air, the actual cooling medium, flows.

Proponents of liquid-cooling–now as in the past–can point to

some benefits and operational advantages such as lessened

hazard of shock cooling an engine, being able to direct

dedicated coolant flow to critical areas in the cylinder head

such as the exhaust valve seat and guide area, flexibility in

radiator placement, greater structural rigidity in the engine,

and having the option of designing airframes with a relatively

small cross-sectional area that could still house a powerful

engine. With every advantage, imagined or real, there is

almost always a price to pay. Those who opted for

liquid-cooled engines had to accept added weight, greater

possibility of battle damage in military applications, and

greater system complexity as the penalties. Such is life.

The general concept of

“liquid-cooling” an engine has remained basically the same

since before the Wright brothers made their historic flight,

except for some significant mechanical, chemical, and thermal

improvements. Those who chose to cool engines by the seemingly

simpler direct transfer of waste heat from the cylinder to the

air have had a much more tortuous and rocky path to follow,

generally speaking. The developers of effective air-cooled

engine installations had to, among other things, invent

effective engine cowlings, conduct extensive studies of the

aerodynamic behaviour of air inside a cowling and around

cylinders, and deal with myriad metallurgical and other

problems in the engine itself in order to extend the life of

critical components. Many choices had to be made with regard

to cylinder structure and arrangement, valve placement and

actuation, the number of valves per cylinder, and the ratio of

heat dissipation between the air and oil, to name but a few.

As in most engineering activities where there is not an

established body of information from which decision-making

assistance can be drawn, wrong choices were made that doomed

some promising engines and drastically extended the

development process of others. Probing the “edge of the

envelope” has never been for the faint of heart.

Inline and V-type engines.

Conceptually, the air-cooled cylinder has always been

associated with low weight and simplicity since no secondary

means of heat transfer was necessary. Pioneer engine designers

were well aware of this and one of the earliest successful

air-cooled aviation engines was the V-8 that Glenn Curtiss

used to power the June Bug in 1908. It reflected the

technology of that era and the individual cylinders with

integral heads were grey iron castings with relatively widely

spaced fins. The choice of gray cast iron as a cylinder

material was logical at that time. Its machining and wear

characteristics were relatively well understood since it had

been used extensively in manufacturing engines of all types.

Curtiss no doubt understood that aluminium would provide much

better heat transfer but it had been in commercial use for

only about 25 years and suitable alloys for producing dense,

strong, heat-treatable castings had not yet been developed.

Also, an aluminium cylinder would have required a cast iron or

steel sleeve, bronze or cast iron valve guides, and valve seat

inserts, making the construction of the engine considerably

more complex. While Curtiss no doubt also understood the value

of deep, closely spaced fins on air-cooled cylinders

regardless of the material used, foundry technology,

particularly the making of baked sand moulds and cores

necessary for such castings, had apparently not progressed to

the point that cylinders of acceptable quality could be cast

consistently.

European thinking tended to

follow the same trends with regard to materials and engine

layout. Renault in France introduced an air-cooled V-8 with

individual cast iron cylinders with integral heads in 1909.

Attempts to increase the power output of this engine brought

on drastic cooling problems that were only partly alleviated

by use of an engine-driven cooling fan. Larger versions of the

Renault engine in V-8 and V-12 form were developed and built

in France and also by the Royal Aircraft Factory in Britain

during World War I, but regardless of size the engines were

characterized by very short exhaust valve life and extremely

high fuel consumption. According to one author, (L.J.K.

Setright) these engines travelled a fine line between thermal

and mechanical disaster.

With the excellent vision

provided by hindsight one can see that the Renault and similar

engines were, to a considerable extent, fuel-cooled as a means

of extending the life of certain critical components,

particularly exhaust valves. This was a common characteristic

of practically all of the air-cooled in-line and V-type

engines of the World War I era. Specific fuel consumption on

the order of one pound. per horsepower per hour at full power

was not unusual. Incidentally, fuel cooling is not a

phenomenon limited to the distant past. Aircraft of the World

War II era powered by large radial engines generally left a

trail of black smoke when the engine was running at take-off

power, a certain indication that some of the fuel was not

completely burned. This generally served to keep cylinder head

temperatures within the prescribed limits and to cool exhaust

valves and other hot spots in the combustion chamber thereby

preventing detonation and/or pre-ignition.

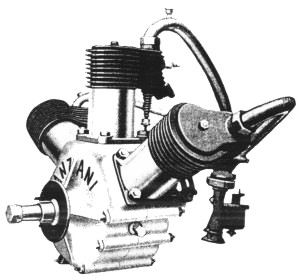

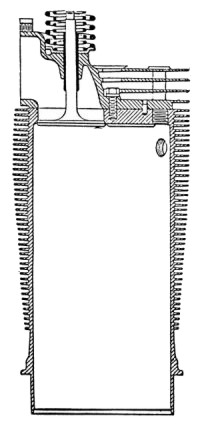

The unusual 3 cylinder Anzani engine that Louis Bleriot used

in his flight across the English channel had cast iron

cylinders with “atmospheric” intake valves and cam-operated

exhaust valves. Note the priming cup on the centre intake

tube.

In 1909, a year that has been

called “the year of practical powered flying” by some aviation

historians, the air-cooled three cylinder “fan type” Anzani

engine powered Blériot's monoplane on its epic 37-minute

flight across the English channel. This somewhat unusual

engine had cast iron air-cooled cylinders with

camshaft-operated exhaust valves and “atmospheric” intake

valves that were kept closed by light springs and opened in

reaction to the differential between atmospheric pressure and

lowered pressure in the cylinder as the piston moved down on

the intake stroke. It is surprising that this type of intake

valve arrangement was used in early aircraft engines such as

the Anzani when in practically all automotive engines of that

era both the intake and exhaust valves were cam-operated. It

did, however, eliminate one pushrod and rocker arm per

cylinder, simplify the cam, and save weight.

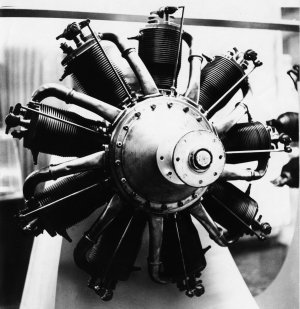

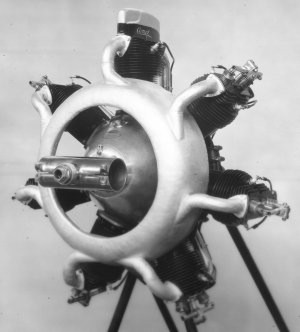

Rotary radial engines. Direct

air cooling was the natural choice for the designers of the

rotary radial engines used extensively in World War I military

aircraft. The machining capability necessary to produce the

cylinders was readily available, and the major parts of the

engine were machined from billets and forgings of alloy steel

rather than from castings. The materials were very likely one

of the low-to-medium carbon steels alloyed with nickel that

were popular in that era. The first of the well-known French

rotaries, the 50 horsepower Gnome, had been flown successfully

in 1909. The power-to-weight ratio of the rotaries was

generally better than that of other aircraft engines, a fact

that made them attractive to aircraft designers. In response

to military needs, larger rotary engines were manufactured in

relatively large quantities in Germany as well as in France

and Britain. Some rotary engines were manufactured in the U.S.

under license agreements with the French. Near the end of

World War I some twin-row fourteen and eighteen cylinder

rotaries had been designed and tested but it is doubtful that

any of these were used operationally.

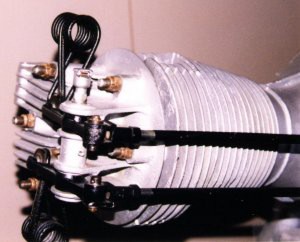

The cylinders of the Le Rhone rotary engine of early World War

I vintage were machined from steel billets and had relatively

closely spaced fins. The single pushrod operated both the

intake and exhaust valves by means of a semi-desmodromic cam

ring.

Since the typical rotary engine

used in World War I fighters turned at about 1,200 RPM at full

power and was enclosed in a partial cowling, the relatively

shallow fins machined as an integral part of the cylinder were

adequate for heat dissipation. The cylinder walls were quite

thin and the head was usually an integral part of the

cylinder, resulting in a clean, simple, and light structure.

There were no exhaust manifolds on rotary engines and when the

exhaust valve on top of the head was open the exhaust gases,

which generally contained liberal amounts of castor oil,

vented directly to the atmosphere inside the partial cowling

used on tractor installations such as the Nieuport and Sopwith

aircraft. Since there was no way to incorporate an oil sump or

any sort of an oil recovery system into the structure of the

engine, the lubrication system inevitably was of the “total

loss” type.

While the rotary radial engine

was quite satisfactory for certain specialized military uses,

its idiosyncrasies–and there were many–made it unsuitable for

commercial applications. By the end of World War I it was

considered obsolete. One of its major drawbacks was that in

operation it produced gyroscopic forces that were a challenge

to many pilots–and a death warrant to some–when controls were

actuated to change the aircraft's direction of flight. Another

basic disadvantage of the rotary engine was that the windage

losses were quite high because of air resistance to the motion

of the cylinders as they rotated. After World War I, surplus

rotaries were readily available but efforts to convert them to

static radial engines were generally unsuccessful since

cylinder head and exhaust valve cooling were very inadequate

unless the cylinder was moving rapidly through the air. Today,

the only operators of rotary engines are dedicated restorers

of World War I aircraft and builders of replicas who strive

for maximum authenticity.

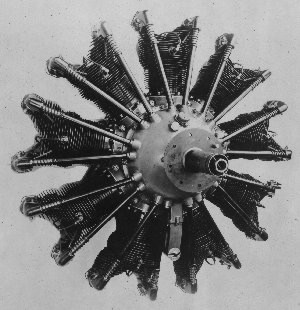

Static Radial Engines. By the

middle years of World War I a number of engine designers in

England had come to the conclusion that the static radial

engine layout offered the best path to developing militarily

and commercially viable engines. There was also support for

the development of air-cooled engines from the British Navy

since Admiralty planners were convinced that such engines

would be lighter for a given power output, easier to maintain,

and less subject to battle damage, a matter of more than

passing interest to pilots flying single-engined aircraft over

water. Incidentally, U.S. Navy planners and aviators came to

essentially the same conclusions in the very early 1920s.

While there was some interest the 1930s and early 1940s in

liquid-cooled engines such as the experimental Lycoming

XH-2470 and Pratt & Whitney XH-3730, a 24 cylinder sleeve

valve engine, it was of short duration. In the U.S. Navy, the

air-cooled radial engine would reign supreme throughout World

War Il and beyond in piston-engined aircraft

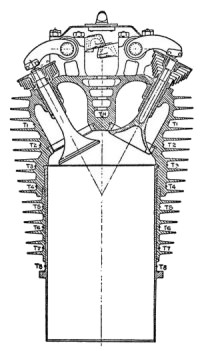

The cylinder developed by Prof. A. H.

Gibson and Sam Heron at the Royal Aircraft Establishment in

1918 had many modem features, including a mercury-cooled

exhaust valve and an aluminium head with relatively deep fins.

Note the unusual valve springs.

The closed-end poultice type cylinder

barrel of the British ABC Dragonfly engine built in

1918 was made of steel and the head was held in place with cap

screws and studs. The intake valve is shown.

During World War I British

military planners and others who saw the need for engines that

could be used in both military and commercial applications had

come to the conclusion that cast iron cylinders were

inadequate. The Royal Aircraft Factory (later called the Royal

Aircraft Establishment), Britain's primary aviation research

facility at the time, was directed to develop new cylinder

designs. Professor A. H. Gibson and Samuel D. Heron, two men

who would have a profound effect on the evolution of the

air-cooled aircraft engine cylinder, were hired. Both

understood that aluminium transmitted heat well and decided

that the head of the cylinder and some of the cylinder barrel

fins should be aluminium castings and that the wear surface of

the cylinder barrel should be a cast iron or steel sleeve.

Bolted joints between the head and barrel were avoided because

of the possibility of gasket failure and leaks in service, a

matter that the manufacturers of the Kinner, Warner, and other

small radials in the U.S. should not have ignored.

By 1918 Heron and Gibson had

designed, manufactured, and tested cylinders that consisted of

open-ended machined steel barrels with an external thread on a

portion of the upper end and a mounting flange on the lower

end. The finned cast aluminium head, which was fitted with

valve seat inserts and valve guides, was internally threaded.

The pitch diameter of the internal thread on the head was

slightly smaller than that of the external thread on the

cylinder barrel so that the head had to be heated in order to

allow assembly. This resulted in a joint that was mechanically

secure at the cylinder's operating temperature and provided

the best escape path for waste heat. In concept, if not in

exact detail, the modem air-cooled cylinder had arrived, but

not everyone was ready to accept it, possibly because of the

“not invented here” syndrome prevalent in some companies.

Some British makers of air-cooled

engines, apparently not realizing what the genius of Prof.

Gibson and Mr. Heron had brought them, cast their lot with

what was known as the “poultice” head design for air-cooled

cylinders. The cylinder barrel was machined from a steel

billet or forging with a flat, closed top end that had

openings that served as valve seats, as in the case of the

unfortunate ABC cylinder. The early Bristol Jupiter

(formerly the Cosmos) was a poultice head engine. On the early

Jupiters, four valves with parallel stems were used,

with the two exhaust valves at the front of the cylinder and

the intakes at the rear. The choice of four relatively small

valves rather than two large ones very likely stemmed from the

belief that the smaller valves would run at lower temperatures

and therefore last longer. The pushrods, rocker arms,

and valve springs were exposed and parts such as the rocker

arm pivot bearings required frequent greasing.

A cast aluminium head that

incorporated the valve ports, valve guides, and rocker arm

stands was attached to the top of the steel cylinder with

bolts or studs. Since the fin area on the Jupiter head

was quite limited, heat transfer from the combustion chamber

to the air was poor and the head required frequent re-bedding

to the cylinder. Engines using this arrangement were never

completely satisfactory although they were widely used in a

number or British and other European aircraft. The Jupiter

was manufactured under license in a number of other nations.

Since poor exhaust valve cooling and relatively short valve

life had been a continuing and vexing problem, the acerbic Sam

Heron once stated that Jupiter consumption should be

stated in terms of pounds of exhaust valves rather than in

pounds of fuel per horsepower/hour.

During the 1920s the Jupiter

cylinder design was subjected to intensive development. Partly

because of experiments with turbo-superchargers on the

Jupiter IV and the introduction of geared internal

superchargers in 1926, it became clearly evident that the

poultice head was inadequate. Bristol finally gave up on the

poultice head design and converted to a variant of the

Gibson/Heron type cylinder at this time and retained the four

valve per cylinder arrangement but with inclined valves in a

pent-roof combustion chamber. It is interesting to note that

the poppet valve Bristol radials were the only radial engines

produced in any quantity that had four valves per cylinder. In

an interesting mixture of old and new technology, the World

War II era Bristol radials such as the Mercury had

partially exposed rocker arms and valve springs mounted atop

forged aluminium heads with machined fins and sodium-cooled

exhaust valves and also had forged aluminium pistons.

Developments

in the U.S.

The Lawrance-Wright Era.

In the U.S., almost the only

proponent of the air-cooled engine during World War I was the

Lawrance Aero Engine Company. This small New York City firm

had produced the crude opposed twins that powered the Penguin

trainers, which were supposed to be the stepping-stone to the

Jenny for aspiring military pilots. The Penguins were not

intended to fly but apparently could taxi at a speed that

would provide some excitement for trainees as they tried to

maintain directional control and develop some feel of what

flight controls were all about. The Lawrance twins, which can

be seen in many museums, had directly opposed air-cooled

cylinders and a crankshaft with a single crankpin to which

both connecting rods were attached. This arrangement resulted

in an engine that shook violently at all speeds and was

therefore essentially useless for normal powered flight. After

World War I, some attempts were made, generally unsuccessful,

to convert the Lawrance twins into usable engines for light

aircraft by fitting a two-throw crankshaft and welding an

offset section into the connecting rods. This proves that the

desire to fly can be very strong indeed in some individuals.

The

cast aluminium cylinder head on the Lawrance opposed twin

engine used on the World War I “Penguin” trainers was attached

to the cylinder with studs. Note the unusual hairpin valve

springs and the adjustable length pushrods.

The hairpin valve

springs pictured on the left were possibly pioneered by

Salmson in 1911, and later used not only on British

single-cylinder racing motorcycle engines, but also by Ferrari

and others into the 1950s. This use was a response to the same

problem that led to desmodromic valves at Ducati, Norton (test

only) and Mercedes - namely the fatigue of coil springs from

"ringing". Hairpin springs ran cool because they were exposed,

and they were less subject to fatigue. They could also be

changed without engine disassembly. Around 1964 cleaner steels

produced by vacuum re-melting became available in quantity,

making possible the manufacture of highly fatigue-resistant

spring wire. Previous wire was made from electric furnace

steel - then the cleanest available. Vacuum remelted steel

wire made desmo and hairpins redundant. Today Ducati engineers

respond to the question "Why still desmo?" much as Bosch

engineers did to the 1945 question "why direct injection when

carbs were so much simpler?". They said that once they'd

started down that road, it was simpler to continue rather than

start over with another technology.

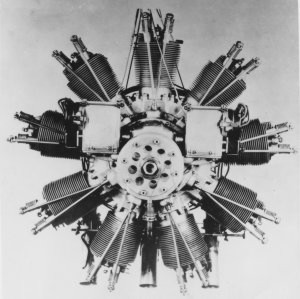

The Lawrance J-1 was the best American

air-cooled engine when it passed its 50-hour test in 1922.

After the end of World War I, the

Lawrance engineers worked with both the Army and the Navy in

developing a nine-cylinder radial engine, the Model J-1.

It was the best American air-cooled engine at the time and

passed its 50-hour test in 1922. A unique feature of the

engine was the use of exhaust valves with hollow stems that

were partly filled with mercury as a means of carrying heat

from the head of the valve through the stem to the valve

guide. Heron and Gibson had experimented with hollow stemmed

valves for a number of years using water or mercury as heat

transfer agents. The use of mercury was not really

satisfactory since it would not wet the surface of the inside

of the valve stem and therefore did not transfer heat well.

Water had been found to be wholly unsuitable.

The early 1920s Wright-Lawrance radial

engine had exposed overhead valves. Note the roller tips on

the rocker arms, adjustable pushrods, and Alemite grease

fittings on the rocker arm pivots.

The U.S. Navy had decided to

build aircraft carriers and since it badly needed light,

reliable engines it gave a contract to Lawrance for the J-1

radial and ceased buying the liquid-cooled Hispano-Suiza

engines manufactured by Wright under license as a means of

pressuring Wright and other companies into developing radial

engines. The Wright Aeronautical Corporation bought the

Lawrance Company, largely at the urging of the Army and Navy,

and the later engines were known as Wrights. These engines,

known as the J series, were dominant in the 1920s and the J-5,

which was the first American production engine to use

salt-cooled exhaust valves, achieved everlasting fame as the

powerplant that carried Charles Lindbergh across the Atlantic.

Samuel Heron, ever on the move,

had emigrated to the U.S. in 1921 after a disagreement with

his employer, J.D. Siddeley of the Siddeley Deasy Company,

over Siddeley's efforts to alter one of Heron's cylinder

designs. It has been said that Heron did not suffer those he

considered fools gladly-or at all- and apparently he did not

make exceptions for employers or company owners. After his

arrival in the U.S. he went to work for the U.S. Army Air

Service at McCook Field (now Wright-Patterson AFB) in Dayton,

Ohio as a development engineer. In 1926, he joined the Wright

Company, of which Lawrance was now vice-president, and his

work in cylinder development was largely responsible for the

success of the Wright J-5 engine. The Lawrance cylinder design

had evolved from an all-aluminium cylinder with a steel liner

that suffered from breakage of the aluminium mounting flange

to the J-5 type that had a finned steel cylinder barrel with a

screwed-on head and much more fin area, especially around the

exhaust valve port. A major step had been taken in improving

the radial air-cooled engine but much remained to be done.

Pratt & Whitney set a new standard for

cylinder design with its first engine, the Wasp

A New Player in the Horsepower

Race. Pratt & Whitney set a new standard for cylinder design

when their first engine, the Wasp (which we now know as the R-

1340 in its military designation) was introduced in 1926. It

incorporated the best features of Heron's latest cylinders and

improvements such as integral rocker arm housings and

additional fin area. That some of the best features of the

Heron cylinder design should appear in this new engine is not

surprising since Pratt & Whitney was formed by F. B.

Rentschler, who had resigned as president of Wright in 1925.

George Mead, Wright's former Chief Engineer, and Andrew

Willgoos, Assistant Chief Engineer for Design, left Wright to

assume similar positions at Pratt & Whitney. The Wasp was an

immediate success and the Navy, by now heavily committed to

building a carrier force, ordered 200 engines, an especially

large order for that era. Almost immediately, the Navy

expressed a need for a larger engine and the 1,690 cubic inch

Hornet was designed and built, passing its Navy type test in

1927. The horsepower race had started in earnest.

Wright responded to this

challenge with an even larger engine, the 1,790 cubic inch

single row direct-drive nine cylinder Cyclone. Its

displacement was soon increased by 30 cubic inches and as the

R-1820, it powered a number of military and civilian aircraft.

Its rated power output rose from about 500 horsepower in 1927

in its original direct-drive form to as much as 1,525

horsepower in the versions produced after World War II. The

author clearly remembers an instance in the early 1980s during

forest fire season when a heavily loaded (very probably

overloaded) ex-Navy Grumman S2F “borate bomber” took off from

the Ramona Airport in southern California on a fairly hot day.

The rate of climb was minimal but the sound of the two very

hard-working Wright R-1820s echo off the surrounding hills was

memorable.

The unique Comet engine, manufactured in

Wisconsin in 1929, had a semi-desmodromic valve actuation

system that required only one push rod and one rocker arm. The

cam ring follower was similar to that used on the LeRhone

rotary engines. Note the fore-and-aft alignment of the valves.

The power output of other engines

that were developed during the World War II period was also

increased substantially. This can be attributed largely to

advances and innovations in cylinder design and construction,

metallurgical progress, and improvements in foundry capability

in the U.S. American foundry men, through intensive

experimentation, had developed procedures for casting thin,

closely spaced fins on a production basis and had progressed

well beyond the British in this critical area. One cannot help

but be impressed, in looking at a World War II era Pratt &

Whitney or Wright engine, at the skill of those who produced

those beautiful cylinder head castings literally by the

hundreds of thousands, and in some cases, by the millions.

The Comet cylinders had the

head cast integrally with the barrel and had a hemispherical

combustion chamber. Note the single rocker stand and the

short, simple ports.

By the early 1930s, cylinder

design in the U.S. for large radial engines had become

somewhat standardized, with bores of about six inches and two

large valves per cylinder in a hemispherical combustion

chamber. Valve actuation was by means of ring cams housed in

the nose section or the crankcase, enclosed push rods, and

rocker arms in individual housings cast integrally with the

cylinder head. While all engines of any consequence had

enclosed valve mechanisms, it wasn't until 1932 that automatic

pressure lubrication with engine oil was introduced on the

Pratt & Whitney Wasp. Much of the subsequent development work

involved experimentation with materials, sodium-cooled valves,

improvements in piston rings, better foundry practices, and

many other minor improvements that would extend engine life

and allow higher power outputs. Near the end of World War II

the much more widespread use of forged cylinder heads with

machined fins was a major factor in allowing engines to be

operated at higher manifold pressures because of the greater

mechanical strength and better heat dissipation capabilities

of such heads.

The cast aluminium head on this late

1930s Kinner engine was attached to the steel barrel by a ring

of studs and nuts. The valve mechanism was enclosed (rocker

covers have been removed).

Engine development has always

been a long, often unrewarding, and always expensive process

that can often be affected by events beyond the designer's

control, such as limited finances or a major war. One of the

inescapable conditions imposed by war is that survival and

victory often depend on the ability to adapt and change

rapidly to meet new challenges. In the late 1930s and

throughout World War II military necessity made performance

the dominant concern, and when cost became a secondary factor

progress was almost inevitably more rapid. The more rigorous

operating conditions revealed weaknesses in cylinders and many

other engine parts that might have remained hidden in normal

commercial use, and by the end of the war the air-cooled

cylinder had very nearly reached its peak in both performance

and durability. Other than direct fuel injection, which came

into relatively limited use in the last years of World War II

and allowed much more accurate fuel-air mixture distribution,

no major innovations appeared since it was becoming

increasingly evident that large radial engines were no longer

of major importance in commercial or military aviation. The

gas turbine had arrived and a new era had begun.

Materials

and Processes, Small Air-Cooled Engines

materials

and processes

Materials and how they were

processed played a major role in the evolution of the

air-cooled cylinder and it was fortunate that the science and

practice of metallurgy had made rapid strides during the

critical periods of cylinder development. Cyclic mechanical

stresses and the process of waste heat dissipation are the two

main enemies of the aircraft engine. Metallurgical and

mechanical improvements were prime factors in extending

cylinder life. The magnitude of the problem was well stated by

an engine developer many years ago who, probably while viewing

some failed parts, described the aircraft engine as a machine

bent on destroying itself mechanically while busily trying to

incinerate its exhaust valves.

exhaust valves

This was definitely the most

trouble-prone and vexing part of the air-cooled aircraft

engine. All engine designers made serious efforts to improve

exhaust valve reliability and durability. Experiments with

internally cooled valves were started as early as 1913.

Initially, water and mercury, as previously stated, were tried

as the heat transfer agents in the sealed, hollow valve stems.

While the material in the stems was almost always called a

coolant, in actuality it was a heat transfer agent used to

carry heat from the head of the valve to the stem where it

could be passed through the valve guide and into the fins on

the cylinder head. As mentioned earlier, water proved to be

impractical and mercury did not work well because it did not

wet the interior of the valve stem and therefore did not

transmit heat well. During his early years at McCook Field the

ever-ingenious Sam Heron had observed the characteristics of

various sodium compounds which are normally used in

heat-treating operations. These materials are solid at room

temperature and become liquid at engine operating

temperatures. He observed that since these compounds wet the

surface of steel alloys readily and transfer heat very well,

their use should be effective in extending the life of exhaust

valves. The ancestor of our present-day sodium-cooled valves

had arrived, thanks to Mr. Heron, and almost ninety years

later we are still enjoying the benefits of his ingenuity

though even today such valves are not completely fault free.

Cylinder barrels

Initially, cast iron was thought

to be the only satisfactory cylinder barrel material but the

builders of rotary radial engines proved that a variety of

steel alloys could be used. Practically all air-cooled

aircraft engines made in the last eighty years have used steel

cylinders and engine developers have concentrated on selecting

the most appropriate alloys and methods of heat treating and

finishing the interior surface. Probably the most widely used

steel was-and is-a chromium-molybdenum alloy generally known

as SAE 4140 (now known as UNS G41400). This material was used

by Pratt & Whitney in the late 1920s and still serves us well

today. It can be used in through-hardened condition or

nitrided depending on the application and severity of service

conditions.

Piston ring shapes and materials

and their compatibility with the cylinder were studied

extensively, especially during World War II and resulted in

development of the keystone ring as well as much more

effective oil control rings. There was also widespread use of

chrome plating of cylinder bores as a reconditioning and

salvage procedure during the war, processes still widely used

on air-cooled aviation engines of all sizes.. It is probably

safe to say that the ultimate combination of piston ring and

cylinder materials has not yet been found, and indeed there

may not be one.

Metallurgy played an important

part in valve and seat development and it was fortunate that a

number of heat and corrosion resistant steel alloys became

available in the 1920s. Materials such as high speed steel, a

cutting tool material that contains as much as 20 percent

tungsten along with molybdenum and several other materials,

and various austenitic stainless steel alloys were used but

none provided the desired degree of durability and resistance

to burning in service. The advent of highly leaded fuels

helped to increase power outputs but also caused serious valve

and seat erosion problems. The solution can be credited in

part, at least, to Mr. Heron and others who were facing the

same problem in England. He used Stellite, a cast cutting tool

material composed of 65 percent cobalt, 30 percent chromium,

and 5 percent tungsten, as an overlay material which was

gas-welded onto the seating area of the valve as well as on

valve seat inserts and finished by grinding. This process

greatly increased valve life and was used extensively during

World War II. It is still considered one of the best

procedures for producing reliable valves and seats for use in

large engines that used leaded fuels.

small

air cooled engines

Well before World War II, it

became evident that for small personal and business aircraft

the radial engine, even in its smallest forms, was not really

a practical source of power. Radials were inherently more

expensive to produce, could not be cowled as easily as opposed

engines, and were generally less economical to operate. In the

late 1920s Harold Morehouse, in conjunction with the Wright

Aeronautical Corporation introduced an opposed twin of rather

archaic design and the Bristol Cherub of about 30 horsepower

became available in England. Very few of the Wright-Morehouse

twins were produced commercially while the Cherub enjoyed some

popularity powering the light sport aircraft of that era.

By the mid 1930s, as the need for

small engines to power inexpensive light aircraft in the U.S.

increased, opposed twins such as the L-head Aeronca E-107 and

the overhead valve E-113, the four cylinder Continental A-40

and its Lycoming counterpart, the 0-145, appeared and a new

generation of opposed air-cooled engines was born. The names

of the smaller radials familiar to those of us who are older-Kinner,

Szekeley, Warner, LeBlond (later Ken-Royce), Lenape (remember

the rare J-3 Cubs powered by the three-cylinder Papoose?),

Velie, and others have faded into the mists of the past.

conclusion

By the mid 1950s or thereabouts,

the evolutionary journey of the air-cooled cylinder for the

large radial engines had essentially ended as the gas turbine

in either turboprop or turbojet form became the dominant

powerplant for larger aircraft. While some large radial

engines are still in use serving as motive power for aircraft

that range from airshow award winners to ratty cargo haulers,

their numbers are decreasing as time takes its toll. The story

is far from being completely told, however, since many smaller

radials such as the Pratt & Whitney R-985 and R-1340 are still

very effectively powering specialty aircraft such as

agricultural sprayers, dusters, seeders and floatplanes that

carry cargo and passengers to and from some of the less

populated areas of our world. It is also interesting to note

that one company is now manufacturing new R-1340 cylinders

with investment cast cylinder heads and that some enterprising

individuals have found a means of adapting Pratt & Whitney

R-2800 front cylinders from B series engines to R-1340s,

allowing an increase in the allowable continuous maximum

horsepower. The story continues, as does the heritage of

Gibson and Heron and of all those who, in the ongoing search

for reliability and durability, surveyed broken or prematurely

worn engine parts and doggedly schemed and worked to produce

better ones.

|