|

aircraft engine

history

a

brief

overview of aircraft engine development

By Kimble D. McCutcheon

During the period between the World Wars, aircraft engines

improved dramatically and made possible unprecedented progress

in aircraft design. Engine development in those days, and to a

large extent even today, is a very laborious, detailed process

of building an engine, running it to destruction, analysing

what broke, designing a fix, and repeating the process. No

product ever comes to market without some engineer(s) having

spent many long, lonely, anxious hours perfecting that

product. This is especially true of aircraft engines, which by

their very nature push all the limits of ingenuity, materials,

and manufacturing processes.

aircraft engine

requirements and measures of performance

In order to compare engines, we must

discuss the special requirements of aircraft engines and

introduce some measures of performance. The requirements are

in some ways contradictory, and therein lies the engineering

challenge. For the purpose of this discussion, we will compare

the Curtiss OX-5 to the Wright R-3350. The OX-5, though hardly

state-of-the-art at the end of WWI, was the first U.S.

aircraft engine to be mass-produced and was produced in such

quantities that war surplus ones powered aircraft for the next

twenty years. The Wright R-3350, completely state-of-the-art

at the end of WWII, had been developed for the Boeing B-29

(the aircraft that dropped the atomic bomb on Japan) and was

widely used in airline service through the middle sixties.

RELIABILITY The first and most important requirement for an

aircraft engine is that it must be reliable. At the end of

WWI, the Curtis OX-5 regularly failed after only 30 hours of

operation. During the 1950ís, airlines often ran Wright

R-3350s 3000 hours. This hundred-fold increase in reliability

is one of the fascinating subjects of this discussion. These

values are usually expressed in Time Between Overhaul (TBO),

but are not really directly comparable. Pilots often ran OX-5s

to failure and forced landings were common. Airlines, on the

other hand, figured a forced landing might scare their

passengers, so they put on multiple engines, kept good records

about how long particular engines could be expected to last,

and presumably overhauled them before they failed. The point,

however, is that engines got much, much better during the

period of our interest.

power

to weight ratio

Secondly, aircraft engines must produce as

much power as possible while weighing as little as possible.

This is usually expressed in terms of pounds per horsepower

(lb/hp). One way to make an engine more powerful is to make it

bigger, but this also makes it heavier. Moreover, if you shave

away metal to make it lighter, parts start to crack, break,

and generally become less reliable. You can see the

conflicting objectives faced by the engineer. Another option

is to get more power from a given size. Engine size is usually

expressed in cubic inches (cu in) of swept volume (the volume

displaced by all the pistons going up and down). If you

can make an engine get more horsepower per cubic inch (hp/in),

then you have made it lighter. The OX-5 displaced 503 cu/in,

weighed about 390 pounds and produced 90 HP (0.18 hp/in, 4.33

lb/hp). By contrast, the R- 3350 displaced 3350 cu in, weighed

3670 lb., and produced as much as 3700 hp (1.10 hp/in, 0.99

lb/hp), improvements of six-fold in horsepower per cubic inch

and over four-fold in power-to-weight ratio. FUEL CONSUMPTION

Finally, an aircraft engine must be fuel-efficient. A great

deal of the take-off weight of an airplane is dedicated to

fuel. So if one can make the engine(s) more fuel efficient,

less fuel must be carried to go the same distance, and more

bombs, passengers or freight can be carried instead. Fuel

usage is expressed in terms called Brake Specific Fuel

Consumption (BSFC). This is the number of pounds of fuel an

engine uses per horsepower per operating hour (lb/hp/hr). Fuel

is measured in pounds because a pound of fuel is always the

same amount of fuel, while a gallon of fuel at 100 degrees

weighs less than a gallon of fuel at 20 degrees. BSFC for the

OX-5 was about .53 lb/hp/hr, while the R-3350 was about .38

lb/hp/hr. If one could compare a ten hour flight under similar

conditions and power settings, one would have to carry 371

pounds of fuel for the OX-5 verses 257 pounds of fuel for the

R-3350, or a savings of 114 pounds. This may not seem like

much of a difference, but again, it is an unrealistic

comparison because of the huge difference in the output of the

two engines. In reality, tens of thousands of pounds of fuel

were carried in the huge transports of the 1950ís, and

improvements in fuel consumption made significant differences

in overall aircraft capability. Indeed, ocean-crossing

airliners such as the Lockheed Super Constellation and Douglas

DC-7 would have not been economically feasible without the

superb fuel consumption of advanced engines.

Areas of

Improvement

So how were these remarkable improvements

made? They were done by systematically improving seven areas

of engine design and construction: Arrangement, materials,

cooling, induction, lubrication, fuels, and operation. Most of

these are necessarily interrelated, as we shall see. In

addition to engine improvements, there were also important

advances in aircraft and propeller design. Perhaps the

greatest engine-related airframe advance was the development

of the NACA cowl that reduced the cooling drag of air-cooled

radial engines to levels that were competitive with

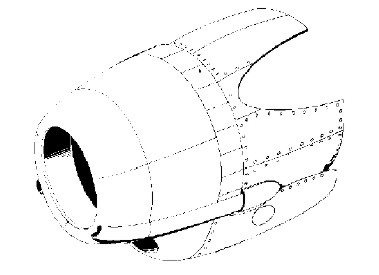

liquid-cooled engines. The greatest propeller advance was the

introduction in the 1930s of controllable pitch and later

automatically controlled constant speed. Constant-speed

propellers allow engines to produce maximum take-off power by

turning maximum RPM due to fine blade pitch, and then cruise

at efficient lower RPM through the selection of a coarse blade

pitch. We will now briefly discuss each of these areas of

improvement. Many of the engines have companion articles that

go into greater technical detail.

Figure 1. The NACA low-drag cowl

Figure 2. The variable pitch propeller

Arrangement

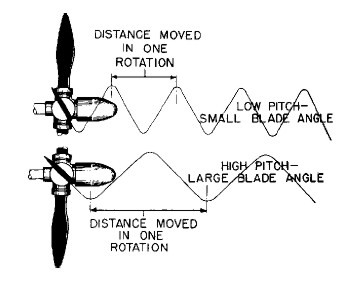

Engine arrangement refers to the

organization of multiple cylinders around the crankshaft.

There are really only two ways of doing this - to put them all

in a row along the length of the crankshaft, as in the inline

engine, or to put them around a single throw of the crankshaft

like spokes in a wheel, as in radial engines. For a long time,

aircraft designers were overly concerned with frontal area of

engines, because this had to be accounted for in the design of

the airframe, and produced drag. In-line, opposed, and V-type

engines provide the least frontal area because cylinders are

"stacked" one behind the other. Unfortunately, any engine

flexes as it runs and must be stiff enough so that it does not

crack its components. This requires a very heavy crankcase and

crankshaft. The radial configuration avoids this problem by

having a short, stiff crankcase and crankshaft.

Figure 3. Engine arrangements

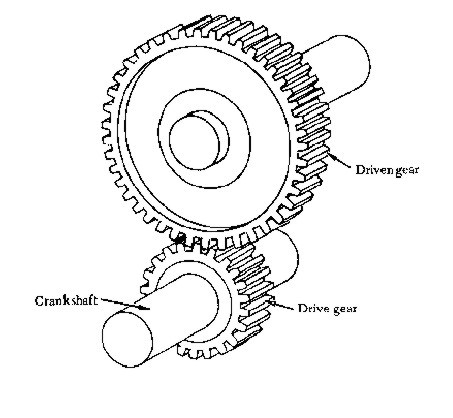

spur and pinion

Figure 4. Propeller reduction gearing

Over time, designers learned to stack

multiple rows of radial cylinders together, and since this had

the best power-to-weight ratio, it became the preferred

configuration for high-power engines. Advances in cowl design

all but eliminated any frontal area advantage of the in-line

and V-type engine. Many other configurations were tried, but

none ever equalled the multi-row radial engine for

power-to-weight ratio. The Curtiss OX-5, Rolls-Royce Merlin

(V-1610), and Ranger V- 70 are examples of V-type engines.

There are many examples of multi-row radial engines, with the

Wright R-3350 and Pratt & Whitney R-4360 being the latest and

most highly refined. There are also many examples of opposed

engines.

While engines are able to achieve higher

power by turning higher RPM, propeller RPM is limited by tip

speed. In order to remain efficient, propeller tips must

remain below the speed of sound. Otherwise, engine power is

wasted overcoming the excess drag of propeller tips making

shock waves and noise. The logical answer to this paradox lies

in the use reduction gearing, allowing the engine to turn

faster than the propeller. Propeller reduction gearing was a

feature of the 1903 Wright "Flyer", but it took a considerable

amount of work to sort out the details of reduction gearing

for high-powered radial engines, particularly multi-row

radials. Each power stroke of the engine tends to slightly

wind up the crankshaft. The propeller resists this winding, or

torsion. When the power stroke subsides, the somewhat springy

crankshaft unwinds producing a phenomenon called torsional

vibration. This plagued early engines, was not very well

understood, and was generally fixed by resorting to huge spur

or helical-cut gears with massive teeth that could resist the

shock loads imposed on the reduction gearing by torsional

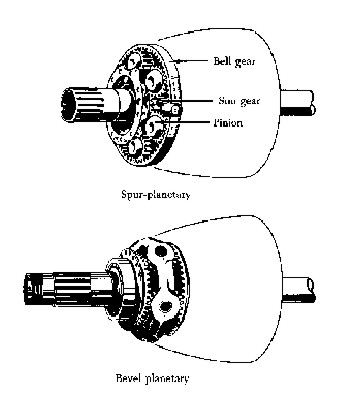

vibration. Later engines saw the development of planetary

reduction gears with very close tolerances that mitigated some

of the effects of torsional vibration. It all came to a head

when controllable-pitch propellers fitted to early Wright

R-1820 Cyclones began breaking propeller shafts. It turned out

that the greater weight of controllable-pitch propellers

increased the effective mass of the propeller and allowed

vibrations of certain frequencies to actually fatigue the

propeller shaft until it broke. The solution was to fit tuned

dynamic torsional vibration absorbers in the form of massive

dynamic counterweights loosely attached to the crankshaft so

they were free to move slightly in the plane of rotation.

Weight and pendulum length were calculated so that the dynamic

counterweight vibrated at the same frequency as the power

strokes of the engine, but out of phase so as to cancel out

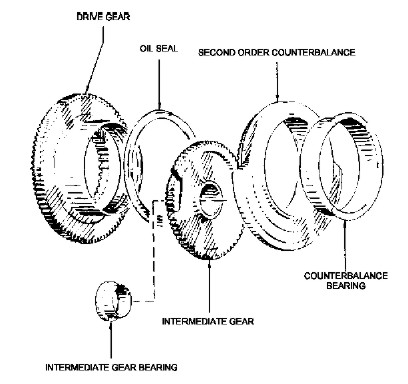

the effect of the torsional vibration. Both the Wright R-3350

and Pratt & Whitney R-2800 encountered another

vibration-related problem. These were the first multi-row

radials with nine cylinders per row, and they too began

breaking engine parts early in development. The problem in

this case was traced to a different mechanism, but was still

vibration related. Radial engines with the master

/articulating rod system produce slightly different motions

for each piston/rod combination, and can never have perfect

balance. This becomes more of a problem as the number of

cylinders per row increases. The unbalance tends to make the

engine move in a circle in the same plane as the cylinders.

Because two-row radials have a two throw crankshaft, two such

motions acting at twice crankshaft speed tend to cause the

engine to wobble about its centre main bearing. This wobble

causes the propeller change its plane of rotation, and

eventually fatigues the propeller shaft to the breaking point.

The solution is rotate correctly sized counterbalances at

twice crankshaft speed and in same direction as crankshaft

rotation.

|

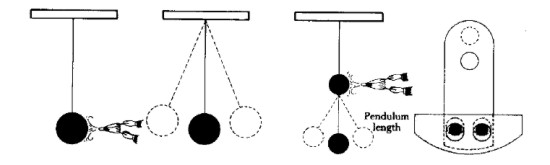

If a

simple pendulum is given a series of regular impulses at

a speed corresponding to its natural frequency (using a

bellows to simulate a power impulse in an engine) it

will commence swinging, or vibrating back and forth from

the impulses. Another pendulum, suspended from the

first, would absorb the impulses and swing itself,

leaving the first stationary. The dynamic damper is a

short pendulum hung on the crankshaft and tuned to the

frequency of the power impulses to absorb vibration in

the same manner |

Figure 5.

Principle of tuned dynamic torsional vibration absorber

Figure 6. Second order counterbalance

Materials

An engine designer, always striving for low

weight, typically makes everything out of the lightest

material that is practical. This usually translates into the

use of aluminium for the bulky components (such as pistons,

cylinder heads, and crankcases) and steel for the highly

stressed components (such as crankshafts, connecting rods, and

gears). Over time, designers created lighter and stronger

alloys, developed ways to harden materials so they lasted

longer, and most importantly, learned ways of forming metal

components so that the "grain" of the metal (metals have grain

just like wood) was correctly aligned to handle the stresses

imposed on the part. This process, called forging, vastly

improved the strength of almost all engine components.

Consider the strength of a crankshaft carved from a single

plank of wood. Though the grain of the wood is in line with

the bearing journals of the crankshaft, the throws of the

crankshaft would be cut across the grain and would be quite

weak. This was the precise problem of early engines.

Crankshafts were machined from giant chunks of steel that had

been hot-rolled so that all the grain of the metal was in one

direction. The forging process takes a hot chunk of metal and

hammers it into roughly the final shape. The metal grain is

forced to conform to the final shape and is much stronger.

Nearly all engines made after 1920 used forged crankshafts,

connecting rods, and pistons. As forging processes became

better understood and huge hammer forges became available,

larger engine parts such as crankcases were forged. The Pratt

& Whitney R-1340 "Wasp" was the first American radial to use a

forged crankcase.

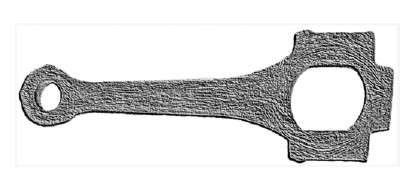

Figure 7. Etched connecting rod rough forging

showing metal flow lines

Further benefits were obtained by improving

the art of casting large chunks of aluminium. In the early

days, crankcases with integral cylinders could not be cast

because no one knew how to make such large castings without

flaws. In-line and V-type engines with the cylinders separate

from the crankcase could never be as stiff as a single large

casting, and consequently, were heavier than necessary. The

Curtiss OX-5 is an example of a separate-cylinder engine while

the Rolls- Royce Merlin is an example of a one-piece block.

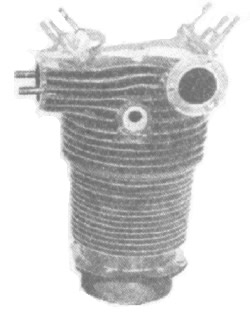

Figure 8. Wright J-5 cylinder

Cylinder heads

are another example of the progress of the casting art.

Compare the Wright J-5 "Whirlwind" with the Pratt & Whitney

R-2800. Each engine has cast cylinder heads, but the fins on

the J-5 are much further apart and much less deep than those

of the R-2800. Considerable experimentation was required to

perfect these extremely complex castings, and much work was

required to produce the pattern and the mould for each one.

The result was an enormous increase in fin area and better

cooling. Later heads were forged, with their fins cut by

special automated machines. Not only were the forged heads

about twice as strong as the best cast ones, but the fins

could be deeper and closer together, resulting in higher

powers and better cooling. Forged heads can be seen on the

Wright R-3350.

Figure 9. R-2800 cylinder

As Pratt & Whitney began to extract more

and more power from their early engines, they began to have

occasional master rod bearing failures in the lead/copper plain

bearings originally used. A massive amount of effort was

thrown into experiments with different bearing materials.

Eventually, it was discovered that a silver bearing plated

with lead and then indium had extremely good wear properties.

In the 1950ís, an airline returned one of these bearings to

Pratt & Whitney for rework after it had run over 7,000 hours.

Pratt & Whitney returned it saying there was no wear,

approving it for continued service. Finally, improvements in

the materials and fabrication techniques for valves made

significant improvements in the power and durability of

engines. Most of this work was done first at the Royal

Aircraft Factory at Farnborough, England and later at McCook

Field in Dayton, Ohio. Experimentation with simple single

cylinder engines determined the best materials and geometry

for valves, guides and seats. The sodium-cooled exhaust valve

was also invented at McCook field. This valve featured a

hollow stem partially filled with liquid sodium. As the valve

opened and closed, the sodium sloshed about, moving heat away

from the head to the stem of the valve. All Wright and Pratt &

Whitney radial engines use this style of exhaust valve.

Cooling

No debate was more heated in engine design

circles than the one over cooling. As with most heated

debates, neither side in retrospect knew what it was talking

about. The choices were liquid cooling, where, as in

automobile engines, the cylinders are surrounded by a liquid

coolant (usually water and anti-freeze) which removes excess

heat from fuel combustion and is circulated to a radiator

where it gives up this heat to the air. Air-cooled engines,

like lawn mowers, have cooling fins on the cylinders, and give

up their heat directly to the air. The subject is complex, and

it took many years to sort it out completely (indeed, it may

still not be sorted out). In the early days, air-cooling was

so poorly understood that almost no one could make it work at

all, and certainly not for any high-power applications. Liquid

cooling at least allowed the production of four or five

hundred horsepower engines. But these were unreliable engines.

The Army, who in those days had the luxury of flight over

land, preferred liquid cooled engines because of their lower

frontal area. The Navy, on the other hand, discovered that

fully twenty-five percent of engine failures were due to

failure of the cooling system, and declared that "Liquidcooled

airplanes make about as much sense as aircooled submarines!"

During the twenties, air cooling became much better

understood, and high-power air-cooled engines flourished to

such an extent that all work on liquid cooled engines ceased,

and both the Navy and Army had to pay premiums to attract any

interest among engine companies an liquid-cooled engines. The

major improvements were made at McCook Field, and appear on

all air-cooled engines since. Innovations included an

aluminium cylinder head with the valves set at a very wide

angle to allow plenty of airflow around the exhaust port. A

steel cylinder liner with machined cooling fins was screwed

and shrunk into this aluminium head, resulting in a gas-tight

seal between the head and barrel. The exhaust valve was the

sodium-cooled variety discussed above. Nearly all aircooled

engines have cylinders of this design (it first appeared on

the Wright J-5 "Whirlwind").

Induction

Induction is the process by which fuel is

mixed with air and introduced into the cylinder. Engine power

is a function of the pressure at which induction occurs. By

forcing more of the fuel-air mixture into the engine at higher

pressure, impressive additional power can be achieved. This

process is called supercharging. Superchargers are pumps that

increase the pressure of the fuel-air charge. In aircraft

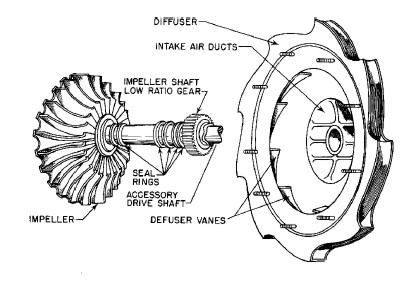

engines, these nearly always take the form of centrifugal

compressors.

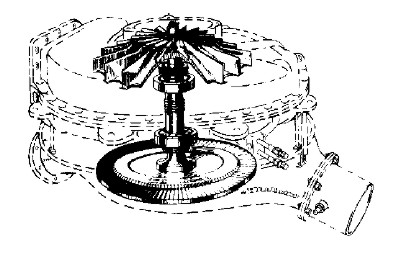

Figure 11. Supercharger impeller and diffuser

Improvements in superchargers greatly

assisted the increased production of power, and also allowed

the engine to produce sea-level power at considerably greater

altitudes than non-supercharged engines. Early superchargers

were just "rotary induction systems", and served little

purpose other than to assure equal distribution of fuel to all

cylinders. As engine development progressed, superchargers

became better and better compressors by providing higher

pressure while consuming less power.

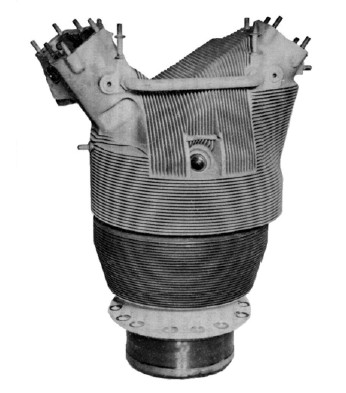

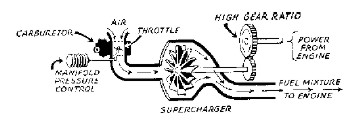

Figure 12. Single-stage supercharger

Supercharger design is a tricky business.

Not only must the supercharger be efficient to avoid wasting

engine power and excessively heating the intake charge, but it

must also have a pressure rise and pumping volume that is

carefully matched to the engine it is a part of. The first

American production engine to use a supercharger was the Pratt

& Whitney R-1340 "Wasp". All early engines used superchargers

from the same source - General Electric. By the 1930ís, it

became clear to both Wright and Pratt & Whitney that the GE

superchargers were very inefficient, and both companies

established their own in-house supercharger design teams.

These designs went on to set records for efficiency and

pressure ratio. As supercharger boost levels improved, the

need arose to tailor supercharger output to the engine power

and altitude. This was the reason for development of two-speed

and two-stage superchargers. The Pratt & Whitney R-2800 in the

F4U Corsair is an example of the two-stage supercharger. The

huge casting behind the last row of cylinders is almost

entirely a two-stage supercharger. Output air from the first

stage is ducted to the second stage for further compression.

An intercooler, which is a sort of air radiator to cool the

compressed intake charge was often fitted to these

highly-boosted engines.

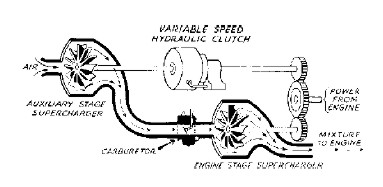

Figure 13. Two-stage supercharger

The huge induction system on big engines

with high boost pressures full of explosive fuel/air mix can

be blown apart by backfires resulting from improper operator

technique. This is one of the difficulties with having the

carburettor at the entrance to the induction system. A more

acceptable solution is fuel injection, preferably directly

into the cylinder. In this situation, the induction system is

just pumping air, so designers do not have to worry about

backfires, uneven mixture distribution, and carburettor ice.

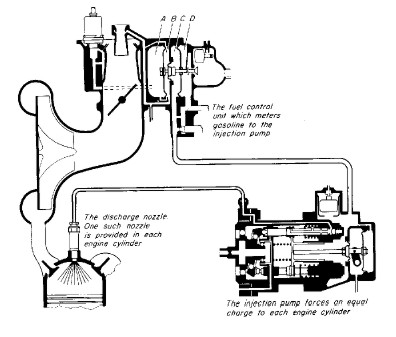

Figure 14. Direct fuel injection

Another type of supercharging that is very

effective is turbo supercharging. In this application, engine

exhaust velocity is used to drive a turbine which is connected

to a centrifugal compressor which rams more air into the

engine. The combined package is called a turbocharger. A valve

called the waste gate controls turbine speed. The turbocharger

has an advantage of not robbing as much horsepower from the

engine as gear-driven superchargers do.

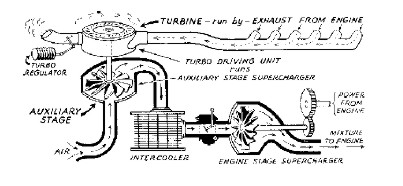

Figure 15. Turbo-supercharger with intercooler

General Electric built all of the

turbochargers used in World War II. All high-altitude bombers

(B-17, B-24, B- 29) and many fighters (P-38, P-47) used

turbochargers to maintain full engine power up to an altitude

of eighteen to twenty thousand feet.

Figure 16. General Electric turbosupercharger

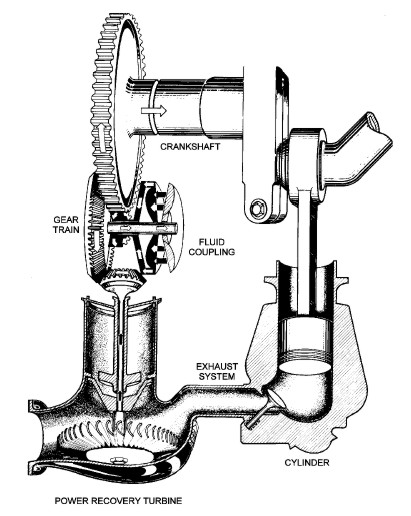

Near the end of World War II, someone got

the idea to harness the wasted energy in engine exhaust by

using the exhaust to drive a turbine that was coupled to the

engine crankshaft. This process is called turbo-compounding.

Although numerous engines had experimental test programs with

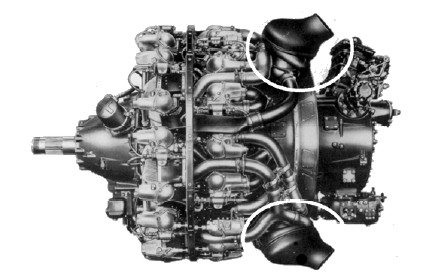

turbo-compounding, only the Wright R-3350 Turbo Cyclone ever

saw wide service. Referring to Figure 18, notice the three

large pressure recovery turbines spaced equally around the aft

side of the engine. Each of these was fed by the exhaust from

six cylinders and contributed nearly 200 additional horsepower

(600 total) to the engine output. Another advantage of

turbo-compounding is the exceptionally good fuel consumption.

Figure 17. Turbo-compounding schematic

Figure 18. Wright Turbo-Compound 18 showing two of three

power recovery turbines

Lubrication

Early engines were lubricated with

vegetable oils usually castor oil. Castor oil was chosen

because it had nearly constant viscosity (resistance to flow)

across its temperature range, and because it coated the metal

surface well so that the lubricating film was not easily

scraped or washed away. It had the unfortunate characteristic

of turning to a gel after being heated and then cooled. For

this reason, it was and still is used only in "total loss"

lubrication systems such as rotary engines, model airplane

engines, and outboards. The introduction of high-quality

mineral oils allowed recirculation of the oil (drastically

reducing oil consumption) as well as the production of greater

power by assuring that metal parts were separated by a thin

film of oil and never came in contact with one another. To do

this, the oil has to be able to resist mechanical pressure,

heat, the tendency to oxidize, and the tendency to lose

viscosity. Originally, only straight mineral oils were used.

In the 1950ís, additive packages were introduced to make the

oil "Ashless-Dispersant" (AD). AD oils leave no residue when

they burn away (hence the ashless) and are formulated to keep

contaminants in suspension until the oil is changed. Nearly

all oil in use today is the AD type. Eventually, synthetic

oils with superior lubrication, viscosity, and stability will

probably replace mineral oils.

Fuels

Of at least equal importance to all other

areas of actual engine development is the development of

fuels. During WWI, pilots noticed that gasoline refined from

Romanian crude oil, ran better than that refined from

California crude. After the war, an investigation of this

phenomenon revealed that "bad" gasoline caused the engine to

detonate. Detonation is a condition in which the fuel-air

mixture in the cylinder burns explosively rather than

smoothly. It was further discovered that pure iso-octane, a

gasoline constituent of a certain molecular structure, was

about the best that could be had. Hence, the Octane rating

system was born. Early gasoline was between 25 and 50 octane.

Combinations of poor cooling, high compression ratios (the

ratio of cylinder volume at the top and bottom of the piston

stroke), and/or excessive supercharging lead to detonation,

often with disastrous results. In the late twenties it was

learned that the addition of tetraethyl lead to gasoline

drastically improved its octane rating, so much in fact that

it was better than isooctane. Fuels that test better than iso-octane

are rated with Performance Numbers (PN) These improved fuels,

often as high as 145 PN, allowed higher compression ratios and

higher supercharger pressures which resulted in doubling or

trebling of engine power. It is interesting to note that the

Allison and Rolls-Royce engines used in WWII Allied fighters

got about the same horsepower from around 1700 cubic inches

that German engines got from 2600 cubic inches. This was

almost entirely due to use of 115/145 PN aviation gasoline in

Allied aviation engines verses the 80-90 octane German fuels.

Toward the middle of World War II, another

technology came on the scene that further improved engine

takeoff horsepower ratings. This was Anti-Detonation

Injection, or ADI. ADI was simply a pump that during extreme

power conditions such as take-off, injected a mixture of water

and alcohol into the induction system. The alcohol was

primarily to prevent freezing of the water. ADI greatly

improved detonation margin, but since it consumed large

quantities of water (which is heavy), it was typically only

used during take-off or for short times in combat.

Operation

The final area of improvement is that of

actual operation of the engine. When the R-3350 entered

service in World War II, it often did not run more than 100

hours before having to be overhauled. In airline service, it

would sometimes last over 3,000 hours. It is true that the

early R-3350s had design problems that were fixed as the

engine matured, but another important factor was how the

engine was operated. The early engines were run very hard and

very hot, often overheated, flown by inexperienced crews, and

maintained by poorly trained mechanics. In airline service,

engines were treated very well, kept cool, flown and

maintained by experienced and competent crew. They were also

better instrumented and better data was kept which allowed

correlation between operational practice and longevity. One of

the most useful instruments introduced during the war was the

torquemeter. This device measured the amount of power actually

being delivered to the propeller and allowed the crew to

select power settings accurately and to lean the engine

correctly to prevent overheating.

Conclusion

By 1950, aircraft piston engines had

reached their pinnacle of development. They had become light,

powerful, reliable, and fuel-efficient. But they had also

reached their pinnacle of complexity and probably power. It is

doubtful that anything larger than the R- 4360 could have ever

been cost-effective simply because of the number of precision

parts and amount of maintenance required. Even the R-4360 was

never popular in commercial service because it typically

required many hours of maintenance for each flight hour, and

sophisticated fault diagnosis equipment to boot. Cylinders

larger than around 200 cubic inches or producing more than

about 200 horsepower were not practical, and engines with more

than about 28 cylinders were not practical. It follows that

engines larger than six or seven thousand horsepower were also

not practical. Around 1945, engineering effort at the major

engine plants began to turn away from piston engines to

engines with much greater potential for development - jets.

|