|

home

home

aero engines

aero engines

Allison W3420s

Allison W3420s

Allison F-80 Trijet

Allison F-80 Trijet

Allison V-1710 Turbo-Compound

Allison V-1710 Turbo-Compound

Clerget Rotary Engine

Clerget Rotary Engine

Curtiss Chieftain

Curtiss Chieftain

Curtiss OX-5

Curtiss OX-5

Daimler-Benz DB 605

Daimler-Benz DB 605

Gnome Monosoupape

Gnome Monosoupape

Lycoming XR-7755

Lycoming XR-7755

Macomber

Macomber

Pratt & Whitney R-2800

Pratt & Whitney R-2800

Wright J-5 Whirlwind

Wright J-5 Whirlwind

Wright Cyclone

Wright Cyclone

Wright Hispano-Suiza

Wright Hispano-Suiza

|

|

Gnome

Monosoupape Type N Rotary

By Kimble D. McCutcheon

An air-cooled rotary that powered a number of

successful World War I aircraft

History

The rotary engine is unique in

that, unlike fixed radial engines, it has a

stationary crankshaft bolted to the firewall, with

everything else (cylinders, crankcase, propeller)

all rotating. The rotary in its original form is

extinct, with the term now being used to describe

"Wankel" rotary combustion engines such as

those built by Mazda. Though automotive and

motorcycle rotaries were built in the United

States and Australia in the 1890’s, the

design was developed for aircraft in Europe.

Laurent Seguin and his brother Louis, of the

Societe des Moteurs Gnome did this in France.

Their engine took the aviation world by storm when

displayed at the Paris Air Show of 1908. By 1917,

rotaries composed eighty percent of the engines

used in World War I (WWI). Originally introduced

as a 50-hp 7-cylinder engine, they developed

rapidly into 80 and 100 hp 9-cylinder engines. A

160 hp 14-cylinder held the world speed record

before WWI. The Gnome was widely licensed, and

copied in many forms by those clever enough

to get around Gnome patents.

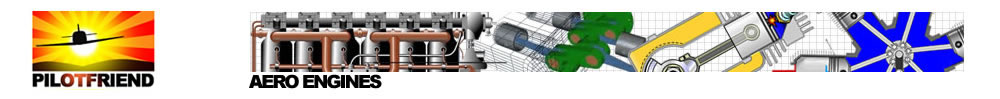

Figure 1. Gnome Monosoupape Rotary

One might ask how such an

evolutionary dead end as the rotary became such a

popular engine. Simply put, it was the right

engine for the time. Its primary advantages, low

weight, relatively low vibration, and reliability

(when properly maintained) allowed the creation of

many new aircraft designs. Early engines, running

on extremely poor gasoline, had low compression

ratios and turned very slowly. Propellers were not

advanced enough to allow more than about 1500 RPM.

At these slow speeds, most early engines vibrated

quite a lot. This was partially because of

unbalanced moving parts and partially because of

so few power pulses per revolution. A flywheel

could have been used to damp out the power

impulses, but would have added weight. Also,

engine cooling was poorly understood in

liquid-cooled engines and understood even worse in

air-cooled engines. So the genius of the rotary

was to reduce weight, provide a flywheel, make the

reciprocating parts move in circles instead of

straight lines (further reducing vibration), and

cool the engine, all with the same construction.

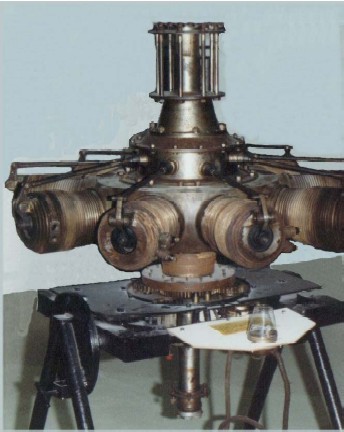

Figure 2. Cylinder Fabrication Sequence

Gnome engines were beautifully

constructed of polished steel, with many finely

machined cooling fins and tiny fasteners. They

were mostly built of forged steel machined to very

thin sections for lightness. Each cylinder, for

example, began life as a 97-pound nickelsteel bar.

When it was completed, it was only 1.5 mm thick

and weighed five and one-half pounds. Similarly,

the crankcase started as a 106 pound forging and

was reduced to a final weight of thirteen and

one-half pounds. Although this fabrication

technique is common in today’s aerospace industry,

it was quite unusual at the time.

Induction

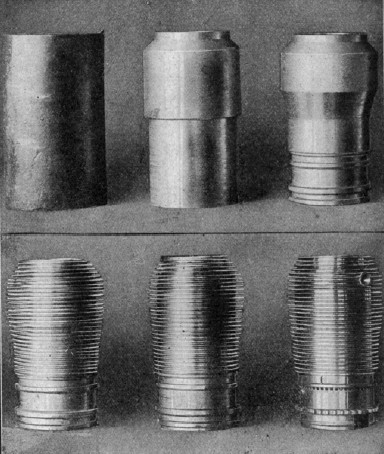

Induction and exhaust in the

early Gnomes was interesting. There was no

carburettor or intake manifold. Air entered the

engine through the hollow crankshaft. A simple

needle valve, in combination with an air valve,

facilitated the pilot’s selection of the correct

fuel/air mixture. This along with lubricating oil

entered the crankcase, was thoroughly mixed by the

thrashing of internal parts, and distributed by

centrifugal force. On each intake stroke,

automatic intake valves in the crown of each

piston opened, admitting the mixture to the

combustion chamber. These valves were

counterbalanced to account for centrifugal force

and piston acceleration, with just the right

balance to allow the suction of the intake stroke

to open them. Once in the combustion chamber, the

mixture was compressed, ignited via a spark plug,

burned to produce a standard power stroke, and

finally exhausted directly to the atmosphere past

exhaust valves in the top of each cylinder. The

exhaust valves were operated by push rods and

controlled by a central cam ring.

Figure 3. Early Cylinder and Valve Details

Since the crude fuel delivery

system had no provisions for throttling, most

rotaries ran at wide-open throttle all the time.

Slight variations in power were possible by

careful adjustment of the fuel/air mixture, and

this allowed formation flight. The aircraft

control stick was fitted with a "blip switch"

which served to momentarily shut off engine

ignition, making powered landings (and go-arounds)

possible. The automatic intake valves of the early

Gnomes turned out to be quite a headache for

maintenance personnel. In addition to presenting a

fundamental limit on engine speed and volumetric

efficiency, they got out of balance easily, gummed

up and got sticky, and worked poorly at higher

altitudes. Thus, they presented constant

maintenance problems, accounting in large part for

the extremely short time between overhauls (TBO).

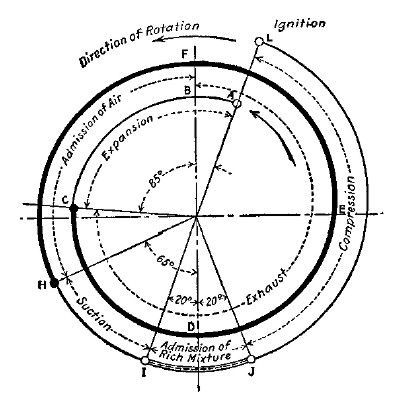

Figure 4. Monosoupape Induction Timing

The Seguin brothers, realizing

these problems, introduced the Gnome Monosoupape

(meaning single-valve) in late 1912. The automatic

intake valve was eliminated and a standard piston

substituted. This piston uncovered a ring of

intake ports at the bottom of its stroke. On the

exhaust stroke, the exhaust valve was opened early

to release pressure and reduce temperature in the

cylinder during the power stroke. When the piston

passed Bottom Dead Center (BDC), the pressure in

the cylinder and crankcase were hopefully equal

and the rich mixture in the crankcase hopefully

did not ignite. The exhaust port remained open for

the entire exhaust stroke and was left open past

Top Dead Centre (TDC) of the exhaust stroke until

about 90 degrees after TDC on the intake stroke

admitting fresh air to the cylinder. The exhaust

valve then closed, allowing the piston to create

suction in the cylinder and ultimately uncover the

intake ports at the bottom of the cylinder. The

very rich mixture in the crankcase was then

transferred into the cylinder via the uncovered

ports where it mixed with the fresh air and was

compressed. Although this technique eliminated the

troublesome automatic intake valves (and may have

contributed to perhaps doubling the TBO of the

engine), it further damaged the Gnome’s already

poor fuel consumption.

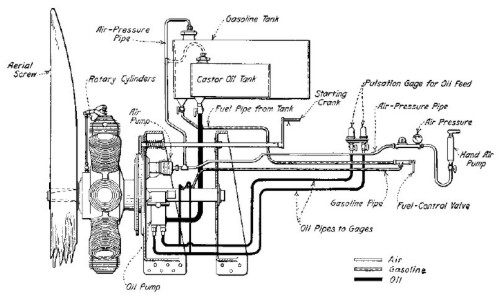

Figure 5. Rotary Installation and Plumbing

click on picture to see full size (opens in new

window)

Lubrication

Lubrication of the Gnome was

accomplished by injecting castor oil into the

fuel/air mix with a small pump. Castor oil was

used because it could not be easily dissolved into

the gasoline fuel, and because it possessed

lubrication qualities superior to mineral oils of

the day. The lubrication system was a total-loss

type, with over two gallons of castor oil being

sprayed into the air during each hour of engine

operation. This explains why most rotaries were

fitted with a three-quarters cowl ring, open at

the bottom. The cowl directed the spray of castor

oil, along with sparks from the exhaust, away from

the flammable airplane structure. In spite of

these attempts to deal with the excess lubricating

oil, pilots were still subject to, and in many

cases the victim of, the well-known laxative

qualities of castor oil. Many unscheduled stops

and off-airfield landings were credited to the

call of nature. Some pilots reportedly kept a

flask of blackberry brandy as an antidote to the

effects of the oil.

Service

The Gnome was, for its time,

light and reliable. Compared to liquid-cooled

engines of the day, it started easily, warmed up

rapidly, and allowed its pilot to become quickly

airborne to do his days bidding (We must not

forget the Gnome was in large part the prime-mover

of a weapons system). Due to the gyroscopic forces

of this rapidly rotating mass, aircraft handling

characteristics in a dogfight were strange. The

craft turned left instantly, but right very

reluctantly. In the hands of a skilled pilot, this

could be quite an advantage in combat. Starting

the engine was an adventure. It was turned over by

hand in a nearly flooded condition, and would

often catch fire due to the excess gasoline. The

fire would typically be confined to the cowl ring

and grass under the engine. The pilot would shut

off the gas and allow the engine to continue to

run on the excess as ground handlers hauled the

aircraft backward out of the fire. All would wait

for the fire to burn itself out. At just the right

moment, the pilot would re-open the fuel valve and

a successful start would have been achieved. When

the engine warmed up, the air valve was opened

wide and fuel re-adjusted to produce a correct

mixture. The engine was then run at full throttle

for the take-off, climb, and cruise, and landed

through the use of the "Blip switch", which was

used to temporarily ground out the ignition.

Though the Gnome was widely used and had a number

of advantages in its particular niche, it also had

a number of problems. It had a very high fuel

consumption so that the total weight of engine

plus fuel and oil placed it at a distinct

disadvantage for long flights. Its performance

fell off rapidly with altitude. Though reliable if

properly maintained, it was extremely

temperamental, requiring skilled mechanics to

overhaul it at typical intervals of 15-20 hours.

It was expensive, with a 70hp motor costing $4000

in 1912! Finally, its rotating mass limited its

size and consequently, its ultimate power. By the

end of the war, when tactics favoured a single

high-speed pass instead of the dogfight,

larger liquid-cooled engines prevailed and the

rotary was rapidly becoming an anachronism.

Specifications (Monosoupape Type

N, 1916)

Configuration: 9-cylinder

air-cooled rotary radial

Output: 160 hp @1,300 RPM

Weight: 330 lb

Displacement: 970 in

Bore x Stroke: 4.53" x 6.69"

Compression Ratio: 5.45:1

Mean Effective Pressure: 100.5 psi

Specific Weight: 2.06 lb/hp

Specific Output: 0.165 hp/in

Fuel Consumption: 29.1 gal/hr @

full power

Specific Fuel Consumption: 1.09

lb/hp/hr @ full power

Oil Consumption: 2.56 gal/hr @

full power

Specific Oil Consumption: 0.12

lb/hp/hr @ full power

6 hr mission specific weight: 1.55

lb/hp/hr (engine + fuel + oil)

|

|