Barrows Bearhawk 260

A Case Study in Refinement

by Budd

Davisson, courtesy of

www.airbum.com

Nasty!

That's the only to describe the wind,

as I lined up on Winter Haven's long

runway. Nasty! It had to be gusting

15-25 knots and snapped from slightly

in front of the right wing to behind

it. Yeah, this was a great kind of day

to fly a new airplane for the first

time. NOT!

On the one hand, it

was a shame the day was so bad,

because I'd been looking forward to

this flight for a long, long

time....for five years, to be exact,

since I last flew the 180 hp version

of the same airplane, the Barrows

Bearhawk. This was a new prototype

with lots of subtle refinements and,

more importantly, 260 hp driving

through a three-blade prop. The up

side to this kind of day was that the

nasty conditions would let me see the

airplane at it's worse. There's no

tougher condition than a

sometimes-quartering tailwind to find

out how evil a tailwheel airplane can

be.

First,

some background. The first time I flew

the airplane was for a pirep in EAA's

Sport Aviation. At the time, editor

Jack Cox and I agreed that the

four-place, straight forward airplane

made a huge amount of sense. 1200

pounds of useful load, good cruise

speed, even better good looks and it

could be scratch built, which would

allow a builder to get into the

finances of the project at a rate he

could afford. That's one of the

downsides of the kit approach: bigger

chunks of change are required to make

it happen. With a scratch built

airplane, such as the Bearhawk, you

can squirrel away a couple hundred

bucks, spend it on tubing and have

enough to build the tail surfaces at

your own speed. Of course, now that

AviPro Aircraft, Ltd. has introduced

complete kits for the airplane, a

builder has the option of building

fast or building cheap.

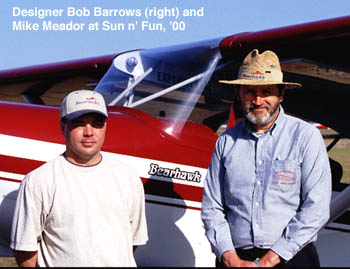

At the time the

first report came out in October of

1995, the designer, Bob Barrows (for

more of his background, go back and

read the first report), had sold

exactly 12 sets of plans. Once the

word went out on the airplane, it

appeared that many others felt the

same way Jack Cox and I had; the

airplane scratched enough aeronautical

itches that plans sales really took

off. As of this writing, May, 2000,

Bob reports they are closing in on 500

sets of plans sold.

The

airplane is fervently supported by the

several hundred builders who are

convinced they are building the most

practical airplane in the homebuilt

catalogue, and they may be right.

If there is a

frustrating aspect to scratch building

any airplane, rather than kit-building

(a situation that may change for the

Bearhawk in the near future, more on

that later) it is that it takes a

longer time for the first airplanes to

start showing up at fly-ins so very

few builder/pilots have had a chance

to fly the Bearhawk. They are building

it on faith. In fact, many report they

are building it based on what we said

in that first pilot report. That's a

pretty heady responsibility and it was

lurking in the back of my mind as I

sat at the end of the runway watching

the windsock whip back and forth.

Would this new version of the airplane

live up to my memory of the first one

and would it justify the enthusiasm of

the rapidly growing group of Bearhawk

builders?

Since Bob had only one set of brakes

in the airplane and a centre throttle,

I opted for the right seat, when we

saddled up. When taxiing out, I was

pleased to see the tailwheel ratios

(he even built the tailwheel itself)

was dead on the money and the airplane

reacted "just right" to rudder input.

Not too slow not too quick. And the

visibility over the nose was great. If

I'd had a one inch cushion, the entire

taxiway would have been in view.

Without brakes, however the residual

thrust of the smoothly idling 0-540

driving through a Hoffman hub with

Bob's homebuilt composite blades, was

enough that I had to ask Bob to poke

the brakes from time to time to slow

us down. Oddly enough, even with the

hard wind, I didn't need brakes while

taxiing crosswind. At the time, I

didn't think much about it, but now,

after the flight, I realize the

airplane was telling me that it had

plenty of rudder even when slow.

Time to go flying!

I smoothly started the power in being

mindful of what the wind was likely to

do to me. I had purposely hunkered

down a little so the side of the

runway cut the edge of the cowling

which gave me a definite reference so

I'd catch the nose if it tried to move

even a little. The instant the

throttle started in however, I nearly

forgot about the runway reference

because the acceleration was

absolutely amazing! It really was a

rush and almost instantly I felt the

tail getting light. Amid the clamour

of an airplane that was obviously

gathering momentum much faster than I

was thinking, I unloaded the stick

intending to gently lift the tail off

the ground. Then, just as the

tailwheel started to leave the ground,

the airplane lunged into the air

clawing upwards at a truly ridiculous

angle. The takeoff actually surprised

me by happening long before I expected

it. Bear in mind, I make an average of

five takeoffs a day in my Pitts, seven

days a week, yet this airplane

surprised me, which is saying a bunch.

I glanced over at

the airspeed and we were already

blasting through 90 mph with the nose

pointed up at an almost scary angle.

Bob has said rate of climb is 1700

feet per minute, but that must be with

a full load, because we were well over

2,000 fpm with two guys and full fuel.

On top of that, I doubt seriously if

we rolled much over 250 feet. Maybe

much less. This is where the nasty day

worked against us: I would have loved

to have played with short field

techniques on a more normal day. I'd

be willing to bet the ranch that using

a three-point takeoff and half flaps,

that thing would leap off the ground

in some unbelievably short distance,

especially with the wind down the nose

instead of coming down the wing tip.

I'm certain that as the throttle went

forward, I could feel the prop blast

"blowing" the mid section of the wing

and that most of the wing came up to

flying speed as soon as full power was

in. The rest of the takeoff roll was

just waiting for the rest of the wing

to catch up.

The instant the airplane launched

itself and we were rocketing upwards,

I threw a thumbs-up signal over at Bob

and yelled, "Fantastic! Absolutely

fantastic!" To say I was loving it was

an understatement. Now, THIS is the

way airplanes are supposed to takeoff

During the takeoff

roll, I wasn't conscious of making any

rudder movements. This might have been

because the right crosswind was

cancelling out any torque induced turn.

In a straight wind situation, I would

expect the right foot to be keeping

the airplane straight with a slight,

constant pressure.

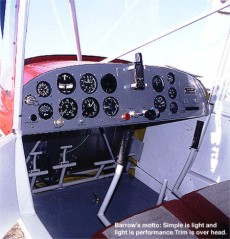

We hit 3,000 feet

in nothing flat and, as I pushed over

and reached overhead to roll in the

trim, I yelled at Bob (he doesn't

believe in intercoms, or electricity

or any of the other "luxuries" most of

us do, which is why his airplanes are

so light) that I was going to set up a

23 square cruise. He shouted back

(it's really noisy in the cockpit and

ear plugs are a must) that he'd like

me to see his normal cruise first.

Before we get into

the "normal cruise" thing, you have to

understand Bob Barrows. Bob doesn't

think speed is worth anything, which

considering how little effect it has

on time actually spent enroute, he's

probably correct. He does, however,

think money IS worth something, so he

doesn't think a pilot should spend any

more than is absolutely necessary.

This includes keeping the airframe

cost down by eliminating anything

costly (he makes his own tail wires

out of turned down and threaded 1/4"

4130 rod and eliminates the clevis

forks by threading thick wall tubing.

See the detail shot. Very effective!).

He also eliminates cost by eliminating

anything that uses electricity and by

keeping the fuel burn down. Simplicity

and low cost are his commandments in

everything he does.

When he set up the

"Bob Barrows Low Buck Cruise

Configuration" he had to fiddle with

the prop a little as it didn't want to

immediately adjust itself. This later

proved to be a couple of blocks inside

the hub that were dragging. His final

setting was 19" manifold pressure and

1900 rpm. This is somewhere well under

50% power, which, as a by product,

brings the noise level way down

because it feels as if the engine is

at idle. The speed stabilized at about

117 mph indicated for about 125 mph

TAS. This isn't exactly lightening

fast, but, Bob grins his

characteristic grin and defends it by

saying, "Yeah, but I'm only burning

7.5 gallons an hour."

Considering that a 180 Lycoming in

cruise burns about 9 gallons/hour this

is something worth thinking about. I

later measured its 23 square cruise

(approx. 60%) at about 155 mph TAS, at

which point it's burning about 13

gallons/hr. Over a 300 mile trip, the

speed difference would save about 25

minutes but the fuel burn would be 8.6

gallons more. At $2.30/gallon that's

$19.78 more. In other words, it cost

$1.32 for each minute saved.

Translated into hours saved, that's

$79/hour saved. Put in those terms,

it's hard to fight Bob's logic. Using

the big 0-540 gives him unreal takeoff

and climb capabilities but lets him

run the engine so far back on the

power curve while still putting out

plenty of thrust that he's doing as

well as, or better than, a smaller

engine in fuel economy. At high

altitude, where the drag comes down

but the engine still has power, the

differences would be even more

dramatic. Like we used to say back in

my drag racing days, "The only

substitute for cubic inches is more

cubic inches."

As I brought the

power up to a more real world power

setting of 23 square, a couple of

things happened. For one thing, the

noise built up considerably. The other

is that as the airplane went through

about 135 mph indicated (145 mph TAS),

the airplane began assuming a nose

down attitude until at a stabilized

145 IAS (155 TAS) the wing was easily

2° nose down, which means, with the 2°

angle of incidence added in, the

fuselage was 4° tail high.

There's been a lot

of conversation about this and it's an

excellent example of how airplanes are

nothing more than one compromise

layered on another. If you want short

takeoff and landing capabilities, the

cruise speed is going to be

compromised and vice versa. Obviously

to take advantage of the Bearhawk's

power at cruise, the angle of

incidence needs to be reduced, this

would bring the tail down 2° which

would result in much less drag and a

higher cruise. At the same time,

however, it would hurt the visibility

in short approach because the nose

would be higher and, when landing on a

short, short runway, the ability to

see and hit the spot is more important

than the actual speed. It would also

hurt the takeoff performance unless

the deck angle was also increased.

Changing the angle of incidence would

have no effect on the wing's nose down

cruising attitude. That is a factor of

coefficient of lift which is a

function of the airfoil section. Going

to a lower lift airfoil (less camber)

would flatten the wing out and give

the airplane much higher cruise

numbers but it would raise the stall

speed and lengthen the takeoff and

landing roll, which is also

undesirable. Clipping the wing a foot

or so would have the same pros and

cons.

After a lot of

bantering on the e-group, it looks as

if the best Band-Aid would be to

reflex the flaps slightly, as Maule

does. With the huge flaps on the

Bearhawk, stowing them at a negative

3-4° would probably do the trick as it

would have the effect of reducing the

camber on a huge section of the wing

during cruise, but would still have

its high lift available on takeoff and

landing. I'd suggest a method of

adjusting the amount of reflex a

degree at a time to match the load and

power available. It could be nothing

more than a sliding ring on the flap

handle that bears on a slightly

tapered ramp on the floor. The entire

reflex mechanism could be very, very

simple. Quite recently a builder in

New Zealand reflexed his flaps 5° and

is claiming a ten knot increase. This

seems high, but five knots seems quite

obtainable.

I wanted to play

with the stalls, so the throttle came

back and the nose went up. Clean,

somewhere down around 50 mph, the

controls went soft and the nose nodded

slightly down. I kept the stick back

to see what would happen and nothing

did. It let me use both aileron and

rudder to control it. With full flaps,

the number came down closer to 40 mph

with only a slightly sharper edge to

the stall itself. This time, just for

the heck of it, I added a little power

and played with slow flight. It took

very little power to hold altitude and

keep the needle nipping at about 45

with nothing in the controls loosening

up or indicating the airplane was

about to do anything stupid.

One of the most

noticeable refinements from the first

airplane was in the control harmony

and feel. The ailerons, which had been

a little stodgy, had been lightened up

by moving the hinge point back. The

result is a nice, responsive,

Beechcraft-like feel with a little

higher roll rate. I'm an aileron freak

and I've got to say that I wouldn't

change a single thing in that area.

They are perfect. Ditto the rudder and

elevator.

It's

overall stability profile is very much

in the middle of the envelope,

meaning, if displaced on any axis it

returns to neutral. It isn't quite as

positive as some airplanes, but it is

much better than most homebuilts and

compares favourably with most factory

Spamcans.

In level cruise,

you're looking down over the nose with

terrific visibility. In turns,

however, you're a fair amount behind

the leading edge and it's really not

convenient to lean forward to clear

for traffic. However, because your

eyes are so far below the wings, you

only have to pick up the inside wing a

little bit to clear for a turn. If

(actually, when) I build a Bearhawk,

it'll have a tinted sky light with a

shade that pulls forward. With no

headliner, you could actually sit

higher for short field work and you'd

be able to see over the down wing in

turns.

The cockpit area,

for those who don't know, was sized to

be slightly bigger than a 172.

However, the panel is quite a bit

lower and you sit higher so all around

room and visibility feels much better

than a Skyhawk. Also, with the cargo

door option in the right side of the

airplane, you can put a huge amount of

stuff in or, roll out an air mattress

in the back and you have your own

three-dimensional camper.

Again, keeping to

his goal of simplicity, the airplane

has no boarding steps. Bob has a

method of boarding in which he puts

his right leg in the airplane past the

control stick, then sits on the seat

edge and brings the other leg in. Bob

is also tall and all legs. Those of us

who are crotch-challenged would

appreciate a step. I think it could be

nothing more than a simple peg or

wedge on the back side of the gear leg

which would allow you to grab the

tubing overhead inside, put your left

foot on the peg and pick yourself up

to put your leg and butt inside. That

might not work, but it needs

something, as I refuse to wear high

heels just to board an airplane.

At some point, we

both knew we were going to have to go

back land the airplane. I wasn't too

worried, but then it wasn't my

airplane.

As I turned final

at 70 mph to cover the gust spread

with only half flaps, we could see the

wind had gotten worse. I could also

see that Bob was getting nervous and I

didn't blame him. The turbulence and

gusts were beating the crap out of us

but it wasn't until we were on short

final and we could see how serious the

wind really was that Bob, using the

most tactful voice he could muster,

shouted, "Do you want me to land it?"

By that time I was

zeroed in on the edge of the runway

and I shouted back without turning my

head, "What ever you think you want to

do, Bob." Inwardly I was grinning

because I could see both of his hands

nervously hovering around both the

stick and the throttle. He wasn't

enjoying this. But, I was. And it was

too late for him to interrupt the

process safely and still land.

There comes a time

in transitioning into any new

airplane, especially in a condition

like this, that you suddenly sense the

airplane's complete character and it

either does or doesn't work for you.

In this case, while Bob was

vacillating about whether to knock me

off the controls and go around or not,

I was looking the Bearhawk right in

the face and I was loving what I saw.

The wind was the

kind that is absolutely dangerous in a

taildragger; hard, sharp gusts and

quartering from the rear. But at no

time did I feel as if the situation

was coming even close to the edge of

the airplane's envelope. I was having

absolutely no trouble flying the line

I wanted; going for a three point

(don't ever wheel land in a tailwind

and I almost never wheel land anyway),

cancelling out the drift, keeping the

tail behind the nose. The airplane let

me do it effortlessly (depending on

your definition of effortless).

As the speed bled

off, it took only a little more wing

down to keep us centred and straight.

Then the airplane painted itself onto

the runway in a single, flowing

motion, right main and tailwheel

first, and stayed there. The airplane

squatted over on all three and it

wasn't until we had slowed way down

that I had to call for some left brake

because the wind had overpowered the

rudder and we were slowly turning

right.

Absolutely no

sweat! I'll take luck over skill any

day!

A note here: very

few airplanes would have given me the

control authority or response to

handle that kind of wind as easily as

we did. If we would have had a better

day, I would have never seen that

corner of its character and wouldn't

have learned as much about it as I

did. I would have liked to have done

some sneaking-over-the-trees short

fields, but I have no doubt it excels

in that, because I did those in the

other airplane. It's very comforting

to know the airplane can handle bad

environmental situations as well as it

can.

I'm more convinced

now than ever that the Bearhawk, with

any engine, is the airplane more

people should be building. It offers

tremendous utility and comfort in an

excellent handling package. Lots of

airplanes are faster, but how many of

them are carrying four people and lots

of stuff? And how many can be built as

inexpensively? If you scratch build,

the steel and aluminium will cost

about $3,500 and that will give you a

complete airframe ready to start

bolting the expensive stuff on. Also,

you can buy that material at the rate

your money comes in. And then there is

the kit route: the quick build is

$25,500 which whacks about three years

off your building time for an

estimated 1000 hour build time.

Do I think the

airplane is worth building? I would

think that should be obvious by now.

Bearhawk Kits

An obvious question has to do with kit

availability. AviPro Aircrarft, Ltd.

is now in full production of kits for

the airplane ranging from complete,

quick-build airframes to complete

wings, wing components, etc. Go to

www.bearhawkaircraft.com for more

information.

Bearhawk

Structure

The Bearhawk is a steel tube fuselage

and welded tail with aluminium, single

strut wings.

The fuselage has

doors on both sides with fold up

windows and a cargo/back door on the

right side. The structure is such that

you tack weld the top and bottom

trusses first, jig it up and put the

side pieces in, rather than doing the

sides first as with most tubing

fuselages.

The tail uses bent

up sheet ribs with tubing spars. The

landing gear has a uniquely simple oil

shock assembly for each leg that

minimizes the amount of machine work,

but works really well.

The plans have no

specifications for seats, but the most

popular seems to be the Tripacer seat

for the front with a variety of

possibilities for the rear. In truth,

almost any kind of seat could be

adapted because the tubing structure

would let you mount any kind of track.

The wings use

folded up "C" shaped spars with

multiple-strap spar caps on the main

spar. Almost all of the skin rivets

are flush and the struts are shortened

C-182 units, although a custom

extrusion is available from Bob

Barrows.

The ailerons and

flaps are fabric covered aluminium and

are actuated through a combination of

cables and push rods, with a minimum

of push rods. There are a number of

steel tubing parts in the wings

including the aileron mounts and

pulley mounts.

The tail wires can

be either streamlined stainless steel

with clevis forks or, a much less

expensive alternative, is to turn down

steel rod as shown in the accompanying

detail photos. Bob is big on building

everything, including the tailwheel

illustrated.

The engine can be

nearly anything, but Bob likes

Lycomings. In fact, building Lycomings

is part of his main business. A

Continental would work just as well

but would require building a bed mount

for it. A number of builders are using

automotive conversions including the

Ford V-6 and Mazda units. It is

entirely practical to build the

airplane with something as small as a

160 hp Lycoming, although the aircraft

would have to be kept light. Flown as

a two place airplane, 160 hp

performance would be surprisingly

good. That would put the airplane at

less than 2000 pounds with full fuel

(55 gallons), for a power loading of

12.5 pounds per horsepower which is

significantly better than a C-172 at

gross (15 pounds/horsepower). The 260

hp airplane at the same weight is 7.7

pounds per horsepower which is right

up there with Pitts Specials. Yeehah!

A note about the

airplane's useful load: Bob's 260 hp

airplane came in at a little over 1100

pounds and he's certain an airplane

with full electrics would come in

under 1200 pounds. This gives it a

useful load of 1200 pounds. Four FAA

sized people weigh in at 680 pounds.

55 gallons of fuel is about 350

pounds. So your baggage/cargo

allowable with full tanks and seats is

50 pounds. You should know one thing

right up front; no one builds an

airplane as light as Bob Barrows. His

finish is thin, his upholstery is

painted Ceconite and he has no radios.

It would be very easy to add 100

pounds with upholstery and radios

which will cut down your useful load.

You didn't hear it

from me, but I wouldn't worry too much

about that. The airplane will carry

anything, but, as long as you stay

somewhere in the neighborhood of

2400-2500 pounds gross, you'll be okay

as the airframe is strong enough to

handle an extra few pounds. Just don't

abuse that margin.

|