Once in a while you have

an experience that so

opens your eyes you

suddenly realize how

little you know about

certain segments of

aviation. And its

exciting! It's damned

exciting to suddenly be

soaking up raw knowledge

in the form of equally raw

experiences which add so

much to your understanding

that the effect is

immeasurable.

I just

had one of those

experiences and it kept me

awake for days designing

airplanes in my dreams.

What has me so fired up?

I just

flew the Sherpa! You

know...that humungous bush

bird which showed up at

Oshkosh last year and

looks like a Super Cub on

steroids. It's the one

with a severe foot

condition.

More

than just flying it, I was

forcefully inserted into

the world of hard core

bush flying for which the

Sherpa was designed. When

I returned home I babbled

on like an idiot about the

experience for hours but

found my tales were split

and focused on two

different subjects: The

first was the Sherpa

itself, but I found it did

no good to speak of the

airplane without putting

it in context. It does no

good to talk about a bush

or utility airplane

without truly

understanding the world in

which it lives because

very few of us really know

what that world consists

of. We may think we know

about bush flying but

believe me, we don't.

I

learned how little I knew

about bush flying and what

it demanded as soon as I

walked up to the Sherpa's

birthplace and company

headquarters; Byron Root's

hangar complex, which was

located mid-field on his

private strip in the

suburbs of Portland,

Oregon. There was maybe

350 feet of runway

extending past the hangars

in both directions with

tall trees at one end

while the last 100 feet at

the other end dropped off

at a steep angle before

disappearing entirely at a

small cliff. The surface

snaked through the trees,

bucking, twisting and

turning as it went, and

had water standing in the

low spots. And this was

their main airport!

Byron

has been building super

bush planes as a side line

(he's actually a real

estate developer) for

years because that's what

he and his friends do.

They jump into their

airplanes and disappear

into the Oregon wilderness

hunting and fishing in

places which have never

seen a road. That means

landing where you possibly

can which in turn means

accepting runway lengths

and surfaces which are an

accident of nature, not

the result of planning or

preparation. Both the

pilot and the airplane

have to be able to handle

what nature hands out. The

only absolute known in

those situations is that

there will never be enough

runway and what there is

will be really rough. As I

found out, sometimes it is

rough beyond the

imagination.

In all

his years bouncing in and

out of river beds and

canyons, Byron learned

from experience what it

takes in terms of the

hardware to both get in

and not break. More than

once he's had to walk

many, many miles for help

after landing somewhere

and having the airplane

break. In conversations

with him certain subjects

continually resurface and

those are what formed the

seeds for the Sherpa

development.

His

list of "musts" for a

serious bush plane

include:

· Lots of power

· Lots of wing

· Lots of flap

· Lots and lots of

structural durability

He

arrived at these through

continually flying

airplanes deemed to be

bush planes and finding

what doesn't work and what

breaks.

For

instance, he doesn't like

spring gear and aluminium

airplanes because the gear

throws up rocks which tear

up the tail and the gear

is too easily eaten by

hidden rocks and holes. He

prefers rag and tube

because it is less likely

to suffer unflyable damage

(duct tape is great

stuff!) and is easier to

repair and beef up.

In his

continual upgrading of his

own Super Cub, he kept

breaking parts and beefing

them up, changing and

evolving the airplane

until today it boasts a

six cylinder, 0-540

Lycoming and what is

essentially a redesigned,

beefed up fuselage.

He and

his friends take their

flying so seriously

they've enlisted the aid

of a radar gun to evaluate

aircraft slow speed

performance. Using the

radar gun they determined

that many of the much

vaunted short field

airplanes, like the Helio

Courier, may be able to

fly really slowly across

the airport, but when it

comes time to land on an

extremely short strip,

they have to come in 5-7

knots faster because they

have to put the nose down

to see the end of the

runway.

As I

was to find out myself,

the ability to see the

exact spot you want to hit

is paramount to short,

rough field work. And you

have to use both words

together, "short" and

"rough" because that's

what defines most bush

strips for the airplanes

that utilize them on a

regular basis.

A few

hours after hooking up

with Byron we were

somewhere out in the

eastern Oregon wilderness

which looks surprisingly

like a desert, but after

drenching rains, it was

all mud. We were sitting

on top a small mesa with

the engine idling and out

in front of me, maybe 250

feet away, was a distinct

semi-ditch where an old

stock road had eroded into

sharp edges. Half way to

the ditch was a narrow

swale I'd have to ride

through. The entire

undulating surface was low

sage brush and mud. Lots

of mud.

Byron was sitting in

the back seat with no

control stick and no

throttle. He had no way to

correct if I screwed up.

The best he could do was

scream into the intercom.

I was going to have to get

off on what was in front

of me and then come back

around and land on what

was behind me. The 150

feet or so behind me

started at a sheer cliff,

went up hill for 30 or 40

feet, and then plateaued

with the ditch at the far

end. We had about 400-500

feet of runway, mud for a

braking surface, and very

little wind on the nose to

help.

Was I

nervous? Surprisingly, no,

I wasn't. I'd seen Byron

make three approaches and

landings and for some

reason, the airplane gave

me so much confidence I

wasn't worried. Byron must

have felt the same way

because I was the first

person outside his company

to occupy the sole pilot

seat and he was turning me

loose in what I thought

was a marginal situation.

Later I was to find that

wasn't the case. 500 feet

wasn't even close to being

marginal.

Byron's

voice was somewhere in the

back of the Bose headsets

(which are an absolute

necessity!) but I wasn't

hearing it. As the

throttle went in, I was

listening to my own voice

inside my head coaching me

as if I was a student.

With 400 horses streaming

out of the IO-720 Lycoming

and over the tail, I just

held on and tried to hold

the tail wheel just barely

out of the mud.

There

is no way you can imagine

what it feels like to be

bounding over rocks and

sage brush and down into a

swale, while hanging on to

a raging bull. My mind was

speaking to my right hand,

asking it to keep gently

applying back pressure,

while willing the airplane

off the ground and away

from the awful beating we

were taking.

The big

tires soaked up an amazing

amount of what I knew were

airplane destroying

impacts, then we bounced

once and were airborne. I

held that attitude for a

second, letting the

airplane accelerate until

it felt as solid as it had

at cruise, before banking

steeply around as we came

out over the yawning edge

of a small canyon. As I

banked I glanced at the

airspeed for the first

time. 55 knots! I thumbed

the electric trim on the

stick forward for a second

and grinned. At that speed

the airplane felt

absolutely stone solid.

The

confidence the Sherpa gave

in that situation was

truly awe-inspiring. I

don't ever remember an

airplane that felt that

good that slow or that

early in a flight It just

seemed so right that I

immediately felt

comfortable, which is not

the way I usually feel

before even making the

first landing. I'm not one

of those super pilots who

are good in every airplane

and this airplane couldn't

have been further removed

from my usual mount, a

Pitts Special, if it

tried. Here I was, 55

knots, 100 feet over a

desolate wilderness in a

30 degree bank in a

machine that weighed

nearly two and a half

times what my Pitts does

and I felt good about it.

Really good. That says

something for the

airplane.

I

stayed low and bent it

around in a tight pattern

heading for the other end

of our so-called runway,

which was nothing more

than a piece of raw

wilderness. I punched the

rest of the flaps out

(40°, slotted-Fowlers) and

trimmed for 50 knots as I

turned final.

The

vertical edge of the mesa

and the short, up-hill

ramp which was my intended

touch down spot was well

up in the windshield. It

was as if the airplane had

no nose the visibility was

so good. Also, the

airplane was so speed

stable, I found cross

checking the airspeed was

a waste of time. As long

as I didn't move the nose,

the needle stayed stuck in

one place. I trimmed it

back to 45 knots, licked

my lips and visually

fixated on my landing

stop.

Not

once in my entire life

have I ever been in that

type of situation, one

which demanded the

airplane hit exactly where

I wanted and for which the

consequences of failure

were so great. Land short

and we'd be a jumbled pile

of junk on the edge of the

mesa (or so I thought at

the time) and the

multi-million dollar

investment of Byron Root

and his partner Glen

Gordon would be gone. Land

long and I'd go slithering

through the mud into the

road/ditch unable to stop

(or so I thought at the

time).

I flew

an abbreviated final but

it took only a few seconds

to realize the airplane

absolutely followed the

throttle, what little I

was using of it. We

weren't grinding along

nose high, with the power

screaming to keep us in

the air. Rather, we were

simply in what would have

been a steep glide but we

were using just a little

power to flatten it out

and overcome the drag.

At 45

knots everything is

happening in slow motion

and it seemed as if I had

all day to gently move the

power in and out to draw a

straight line to my

landing spot. Then,

suddenly we were there and

the spot loomed large in

the windshield. I gently

brought the nose up and

eased the power off (Byron

had demonstrated it needed

just a bit of power to

flair). We flopped into

the mud with me sucking

the stick into my gut and

the airplane had nearly

stopped rolling before it

dawned on me to get on the

brakes.

I let

out the breath I had taken

on downwind and grinned

about as wide as I believe

I have ever grinned. What

an absolute, positive,

unqualified blast! I

looked ahead at the

road/ditch I was worried

about and realized I had

more distance left to

takeoff than I had the

first time. We hadn't used

much over 150 feet on

landing and I didn't know

what I was doing! That

says a lot for the

airplane.

I made

a bunch more take-offs and

landings on top that mesa

before trading places with

Byron so he could show me

how the airplane really

flew.

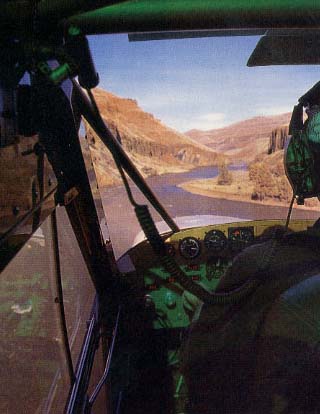

I was feeling like a bush

pilot until we dropped

down into a canyon and

started buzzing along

right over a serpentine

river 1,000 feet below the

rim. We did our eagle

routine and twisted and

turned right along with

the river. As we did,

Byron was pointing out

gravel bars and small

spaces along the bank they

used as landing spots

while fishing. That's when

I knew I was no bush pilot

and why Byron was so

willing to let me flop

around in the mud on top

the mesa...the spots he

was pointing out weren't

large enough or smooth

enough to orchestrate a

crash, much less a

landing. At least that's

what I thought.

Just to

prove a point, Byron

pointed out a small speck

of gravel sticking out of

the water and said that

was a good spot for

steelhead fishing. He ran

out all the flaps, pulled

up over a rock ledge

sticking out of the side

of the canyon, floated

around in a tight turn and

dropped down close to the

surface of the water. From

the back seat, I never saw

the gravel bar until our

big baloney tires crunched

onto it at the edge of the

water. We bounded along

over the incredibly rough

surface for less than half

the length of the gravel

bar. I paced off our

landing roll as 110 feet.

We were two people, 85

gallons of gas, 65° F and

3,500 ft MSL. I had

trouble pacing off the

distance because the

surface was comprised

entirely of water-worn

rocks the size of

cantaloupes and I was

afraid I was going to

break an ankle!

This

was the kind of surface

that, according to Byron,

eats stock Super Cub

structure and it was easy

to see why. Even with fat

tires, the Cub's structure

just wasn't designed for

those kinds of loads,

especially around the tail

post.

Byron

also says fully loaded to

4,750 pounds (2,200 pounds

usable) the airplane will

still get into or out of

anywhere you'd dream of

putting a Super Cub and

loaded to lower weights

can go places you wouldn't

dare take a stock Super

Cub. In most situations it

will even out fly his big

engine Cub.

Undoubtedly the most

impressive part about the

airplane is the ease with

which a pilot could learn

to handle it in the bush

environment. The controls

are very normal feeling,

meaning neither light nor

heavy and the airplane

responds surprisingly

quickly for an airplane

that size. They have a

number of aerodynamic

changes in the works to be

completed before

certification which

include a longer tail

moment to take care of the

reduced tail efficiency at

full flap extension and a

larger wing with more

flap. Their aerodynamicist

says they will trim

another 6 knots off the

stall speed with the new

wing. Considering they

have radared the airplane

as flying 34 mph

(power-on), a 6 knot speed

reduction would make the

airplane even easier to

get in and out. In fact it

would be the next best

thing to a helicopter,

which it is already. Byron

says their goal is an

airplane that can get off

in less than 100 feet,

zero wind with 500 pounds

on board. As it is, with a

ten mph wind they can do

that in 72 feet!

It's

this last point, the

comparing of the

airplane's utility with

that of a helicopter, that

continually bounced

through my mind during the

day. With the possible

exception of landing on

roof tops and tennis

courts, the Sherpa could

do probably 80% of what a

helicopter does with a

fraction of the purchase

and maintenance cost and

with much less chance of

equipment breakage in the

field.

When we

were enroute back to home

base I noticed a curious

change had taken place in

my mind. I found myself

thinking like I used to

when flying a Super Cub on

skis after a major snow

storm. In that situation,

with skis and lots of

snow, everything flat is a

runway. You can land

everywhere. On the way

back with the Sherpa, I'd

look down and see a small

flat spot and think,

"...we can land in that

easy..." It was a very

comforting feeling.

And

when I saw a small remote

town without a runway, I

realized it didn't need a

runway for emergency

medivac situations. There

were a dozen flat spots

within city limits where

the Sherpa could land with

no sweat. A football field

becomes an

airport...literally!

The

Sherpa is also faster than

all but the most exotic

choppers. We were showing

120 knots, which at that

altitude and temperature

was a shade over 140 knots

true. Incidentally, while

we were cruising along at

altitude, the visibility

in all directions was

amazing. The nose is way,

way down and the glass

doors let you look

straight down. Byron said

the fish and wild life

boys who were evaluating

the airplane would go for

the standard 29 x 11 x 10

tires because they

wouldn't block as much of

their view. He also said

they were working on a

curtain/shade for over the

pilot's head because he is

out in the Plexiglas and

gets pretty hot.

Ignoring the airplane's

ability to work in the

bush, I'd be very

surprised if government

agencies, both ours and

other country's, didn't

jump on this bird as one

which could replace

helicopters and other

fixed wing airplanes for a

lot of use where

ultra-short runways aren't

even a factor. At 45 knots

it is slow enough to do

bird counts, pipeline

patrol, border

surveillance and on and

on. It is also an airplane

almost anyone can fly

easily since its ground

handling is so benign.

I think

these guys are really onto

something!

Sherpa Tech Specs

Structurally the Sherpa is

a rag and tube fuselage

and metal wings (airfoil

43015A Modified) with 120

gallon (to be increased to

180 gallon!) fuel tanks.

But this is a serious tube

fuselage...the longerons,

for instance, top and

bottom are 1 1/4 "x .058".

Everything about the

airplane is built tough to

take a beating.

The

landing gear, besides

being massive, utilizes a

shock absorber along with

the bungees to dampen

rebound. This shock is not

an air/oil oleo because

that wouldn't let the gear

come back to rest quickly

enough after hitting a

rock. The gear might still

be partial extended when

it hit the next one. The

Sherpa shock uses urethane

washers which have a more

immediate response.

The

elevator trim is electric

utilizing dual screw jacks

and the flap motor looks

big enough to move a

house. It takes about 9

seconds for extension and

ten to retract them.

The

Lycoming IO-720 engine is

an enigma to most of us

because most of our

knowledge of it comes from

its use in the Commache

400. There it had a less

than enviable reputation

largely because it was

tightly cowled and prone

to over heating. The

Sherpa team has utilized

the experience of numerous

Piper Brave ag operators

in the area which swear by

the engine. They say they

go to 2,000 hr TBO will

few problems. While we

were flying the airplane,

in ten hot-starts, it

never hesitated.

They

have gone through a number

of propellers and have yet

to finalize the selection.

The four-blade they had on

the airplane during our

evaluation wasn't putting

out as much thrust as

their earlier Hartzell

three-blade had.

Some

foreign governments have

expressed an interest in a

turbine installation, but

no one at Sherpa is wild

about the idea. Besides

doubling the cost of the

airplane, they say its not

going to improve its

performance enough to

justify the cost except

possibly on floats.

The

tires can be either the

standard 29 inch, aircraft

versions or the baloney

skin tundra tires like we

flew. Those are actually

four-wheel truck tires

with the tread ground off

mounted on 15 inch

aluminum, one-ton Chevy

truck rims. They say they

have been flying that type

of tire for nearly 15

years with little or no

problems. The brakes are

two, three-spot calipers

on each wheel.

The

tailwheel is a standard

500 x 5 main gear unit and

the tailwheel assembly is

something that is

undergoing continual

revision. Because of the

airplane's weight and the

surfaces they intend to

work off of, nothing

commercial has stood up so

they've left a lot of

tailwheels up in the

canyons. Presently they

are testing their own

assembly which utilizes a

CNC'd 7075 pivot with a

4130 weldment fork.

The

airplane is currently

configured for a 1-2-2

seating arrangement but

the seats are actually

wide enough for three

across in a tight squeeze.

The single front seat will

be changed to a side by

side arrangement for those

who want it along with a

sliding, side opening door

in the rear of the

fuselage for passengers,

cargo or litter cases.

Knowing what little I know

about bush flying at this

point, I'd rather have the

single pilot seat so both

sides of the nose are

visible on landing.

The

floors are a honeycomb

sandwich and production

airplanes will have a

multi-use track system

which would allow easy

removal or repositioning

of seats as well as cargo

tie down. The cargo space

aft of the pilot's seat

will accept the equivalent

of five 55 gallon drums.

Useful load is just short

of 2,200 pounds!

It's

some kind of hoss!

Wing

Span 42.6' (present wing)

Wing Area 258 (to be

increased)

Fuel Capcity 121 Gal (180

in production)

Empty Weight 2585 lbs

(includes survival gear,

tools, etc)

Gross Weight 4750 lbs

Useful Load 2165 lbs

Performance

Takeoff roll (3,000 lbs.,

0 mph wind) 135'

Landing roll (3,000 lbs.,

0 mph wind) 145'

Takeoff roll (3,000 lbs.,

10 mph wind) 72

Landing roll (3,000 lbs.,

10 mph wind) 77'

Takeoff roll (4,750 lbs.,

0 mph wind) 396'

Landing roll (4,750 lbs.,

0 mph wind) 282'

Takeoff roll (4,750 lbs.,

10 mph wind) 272

Landing roll (4,750 lbs.,

10 mph wind) 191'

Cruise speed, 75% 160 mph

Fuel burn, 75% 20.1 gph

Economy cruise 15.5 gph